Project Overview

A leading subsea services provider selected MCS for a large-scale subsea metrology project in the Gulf region.

The project involved the installation of more than 50 subsea spool pieces for two prominent clients in the area.

The objective was to ensure accurate and efficient installation of the spool pieces using MCS's innovative Photo Realistic 3D Cloud (PRC) technology.

This case study highlights how the subsea services provider utilized PRC technology to carry out the installation of one of these subsea spool pieces and the resulting outcomes.

Challenges

Measuring and installing the closing spool

The EPC contractor faced the challenge of installing multiple subsea spool pieces, with the closing spool being of utmost importance for connecting the new wells to the facility plant.

The closing spool needed to be accurately measured, designed, fabricated, and installed within the shortest period possible to ensure the connection of new wells to the facility plant.

Traditional subsea metrology solutions often resulted in delays, rework, and increased costs, necessitating a more efficient and accurate solution to meet the project’s requirements.

Solution

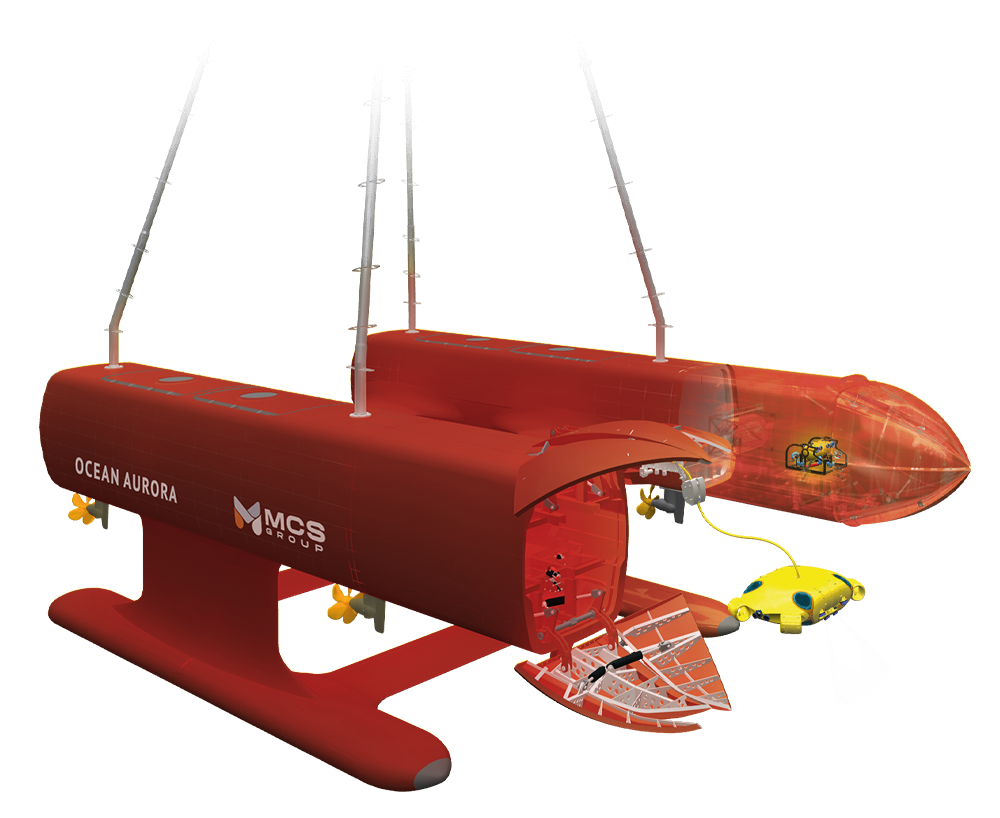

Deployment of MCS Photo Realistic 3D Cloud (PRC).

Utilizing our innovative Photo Realistic 3D Cloud (PRC) technology, we offer a comprehensive solution for scanning underwater structures and pipelines. Our state-of-the-art technology creates precise 3D representations with accurate measurements, reflecting the as-built or as-found condition of the scanned objects. To overcome challenges, MCS followed these steps.

- PRC system can integrate with any ROV: PRC system was seamlessly integrated with Work-Class ROV, enabling efficient data acquisition in the subsea environment.

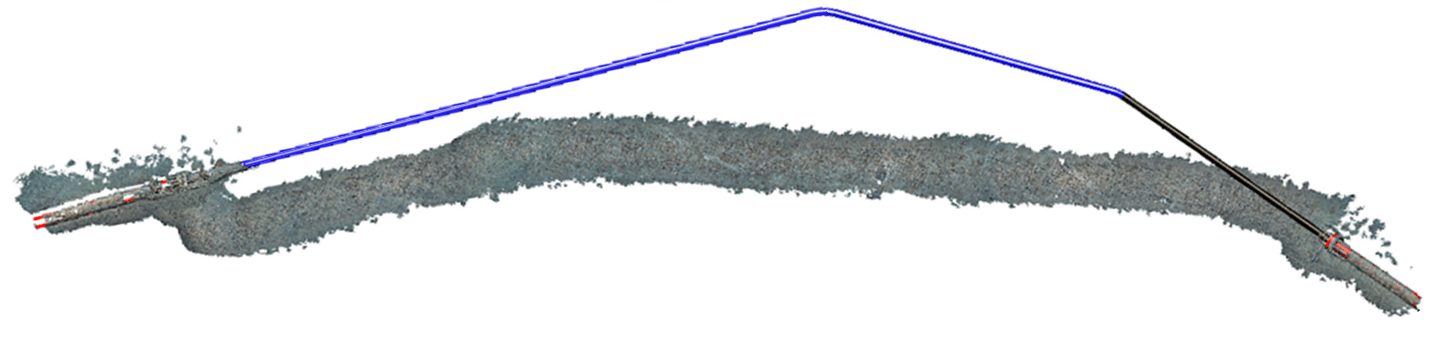

- Comprehensive survey data capture: The PRC system was initiated to capture comprehensive survey data of the subsea spool installation area.

Figure 1: Point Cloud Model by PRC technology for the spool - Top View

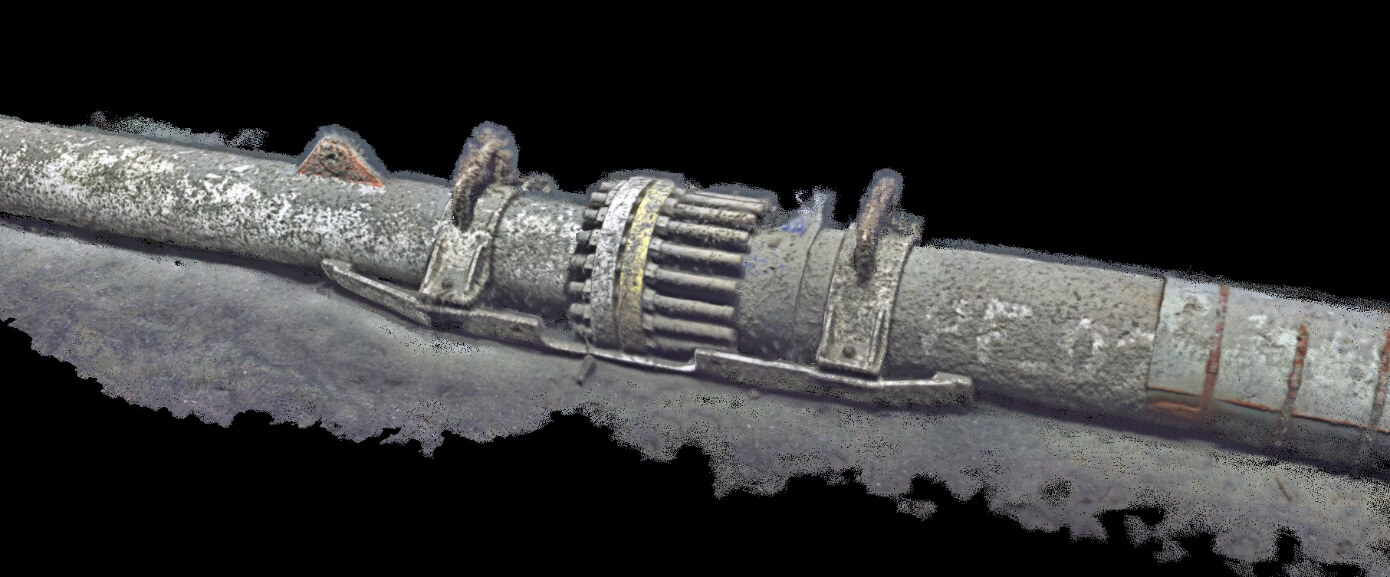

- 3D image scan of connection flanges: PRC conducted a precise 3D image scan of the connection flanges to meet the spool’s requirements, capturing accurate measurements and detailed geometry information. The 3D point cloud data formed the foundation for design and fabrication.

Figure 2: Point Cloud Model by PRC for Pipeline-side-flange Connected to laydown head.

Figure 3: Point Cloud Model by PRC for spool-side-flange.

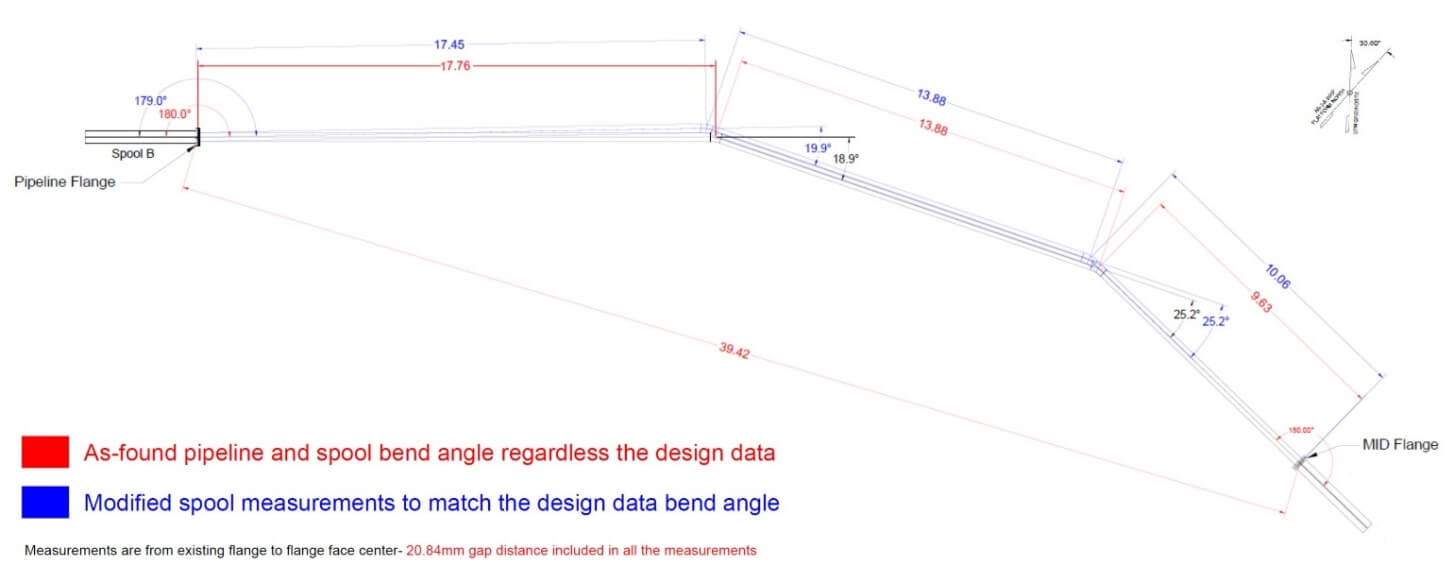

- On-Site Design of the closing spool: MCS utilized detailed 3D PRC data and preliminary design reference to design the closing spool on-site, ensuring optimal fit, alignment, and integrity of the subsea system.

Figure 4: Simulation of the Spool installed on the flange.

- Fabrication of the spool: Once the design was complete, the field engineer reviewed and approved it, ensuring safety and operational compliance. The pipe-fabricator utilized the design information to fabricate the spool efficiently, minimizing waste and potential delays.

Outcomes

The utilization of MCS PRC technology for the spool metrology project in the Gulf yielded the following outcomes:

- Enhanced accuracy: The PRC technology ensured the precise fit and alignment of the closing spool with connection flanges, reducing leaks and enhancing the long-term performance of subsea infrastructure. Deliverables, including an AutoCAD file, detailed report, and 3D point cloud, provided precise measurements, as-found data, and detailed geometry information, ensuring reliable analysis, minimizing human error, and optimizing the design, fabrication, and installation processes.

- Reduced Cost and Time: Compared to traditional subsea metrology solutions, the use of PRC technology proved significantly more cost- and time-effective. The accurate measurements and detailed design information derived from the 3D scan minimized the need for rework and adjustments, reducing material waste and labor costs. The streamlined design and fabrication process also contributed to overall cost savings and a shorter project timeline, providing significant benefits to both clients.

- Improved safety: PRC technology eliminates the need for divers, improving safety and addressing challenges related to worksite depth, environmental conditions, and measurement complexity, ensuring consistent accuracy, and reducing project risks.