MCS has more than 20 years’ experience in subsea data management and inspection of underwater structures. We have designed a cutting-edge software system for data acquisition and processing to overcome challenges in the inspection and reporting of underwater pipelines.

20 Yearsof subsea inspection

100000KmSubsea pipeline systems inspected

80Customers

Capabilities

_

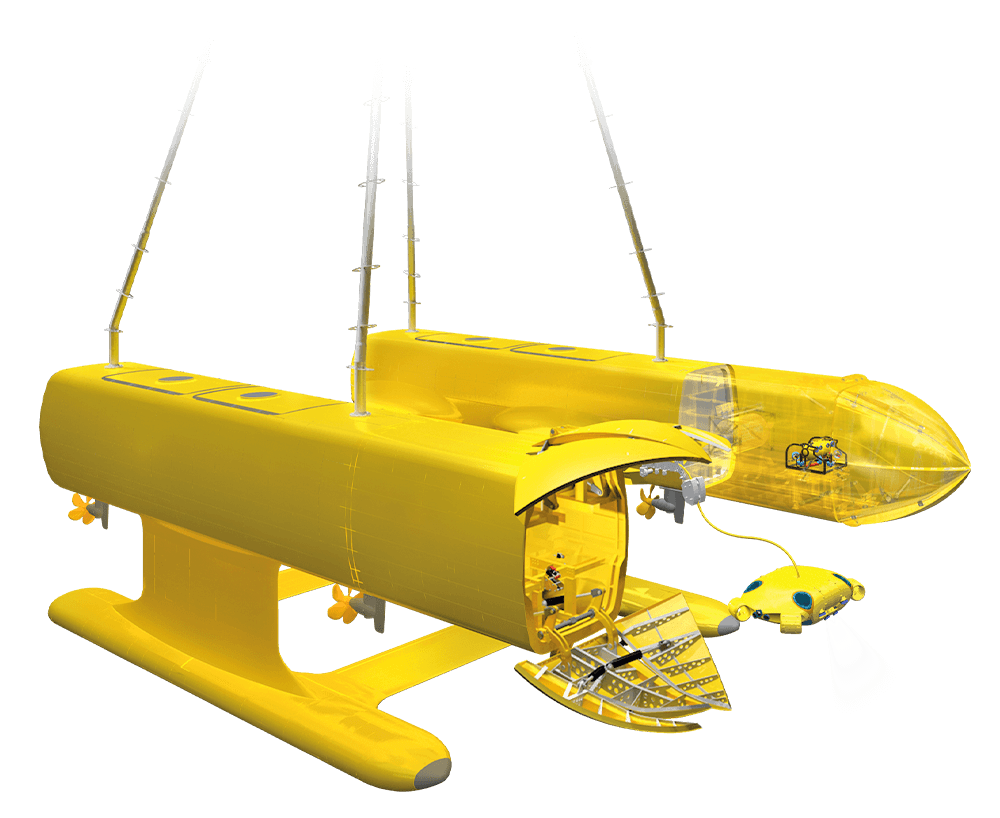

Our fully integrated Pipeline Commander system is a planning and management tool for the inspection and condition monitoring of underwater pipeline cables, flexible lines and flying leads throughout their entire life cycle. Three modules including data acquisition, processing and deliverables provide bespoke charts, reports, and real-time viewing at your fingertips. The system streamlines data from multiple ROV cameras and combines them into one extremely accurate, synchronized 3D visualization, within a user-friendly interface.

Types of inspection / survey :

- Damage to risers, pipelines, or coatings.

- Dented, bent, kinked, or buckled pipe.

- Corroded or leaking pipe or CP.

- Free span correction.

- Pipeline crossing.

- Pipeline Pre-lay.

- pipeline as-laid.

- pipeline as-built.

- Pipeline expansion loops.

- Pipe support device.

- Major debris on or near the pipeline.

- Valves tie-ins and protection cages.

- Expansion joints.

- Buckle arrestors.

- Temporary or permanent repair clamp.

Benefits

_

Optimize efficiency

Increase efficiency with real-time viewing, highly accurate data and automatic data processing with advanced algorithms for faster reporting times.

Reduce cost

Reduce the reliance on equipment and people offshore and save money.

Secured

Combine this flexible and secure technology with our experienced data processing personnel.