Enhance Efficiency and Cost Savings with MiniSpector® for Pipeline Touchdown Monitoring

Project Overview

A leading energy entity in the Middle East, renowned for its expertise in exploration, development, and production activities within the oil and gas sector. MCS Group presents a case study on the application of the Minispector® by and operator in Egypt. Utilizing the Minispector® Mini-ROV, The client efficiently carried out a 6'' pipeline touchdown monitoring survey and As-Laid survey. This method allowed for prompt identification of issues during the pipeline installation, enhancing operations and mitigating risks.

Challenges

Addressing Technical Limitations

The client’s objective was to conduct a 6” pipeline touchdown monitoring survey and As-Laid survey to ensure the pipeline’s correct placement on the seabed. The primary objectives were to detect unexpected obstacles during the pipelay process and verify the integrity of the pipe. However, the client encountered 2 major challenges that threatened the successful completion of the project:

- Navigation System Deficiency: The absence of a navigation system made it challenging for the client to accurately determine the pipeline’s position, complicating the monitoring process.

- Unavailability of a DP Vessel: The client faced an obstacle in procuring a Dynamic Positioning (DP) vessel, a crucial component that often accounts for 90% of the monitoring expenses.

These challenges listed above posed a significant hurdle to the project’s feasibility.

Solution

Targeted Strategy for Optimal Results

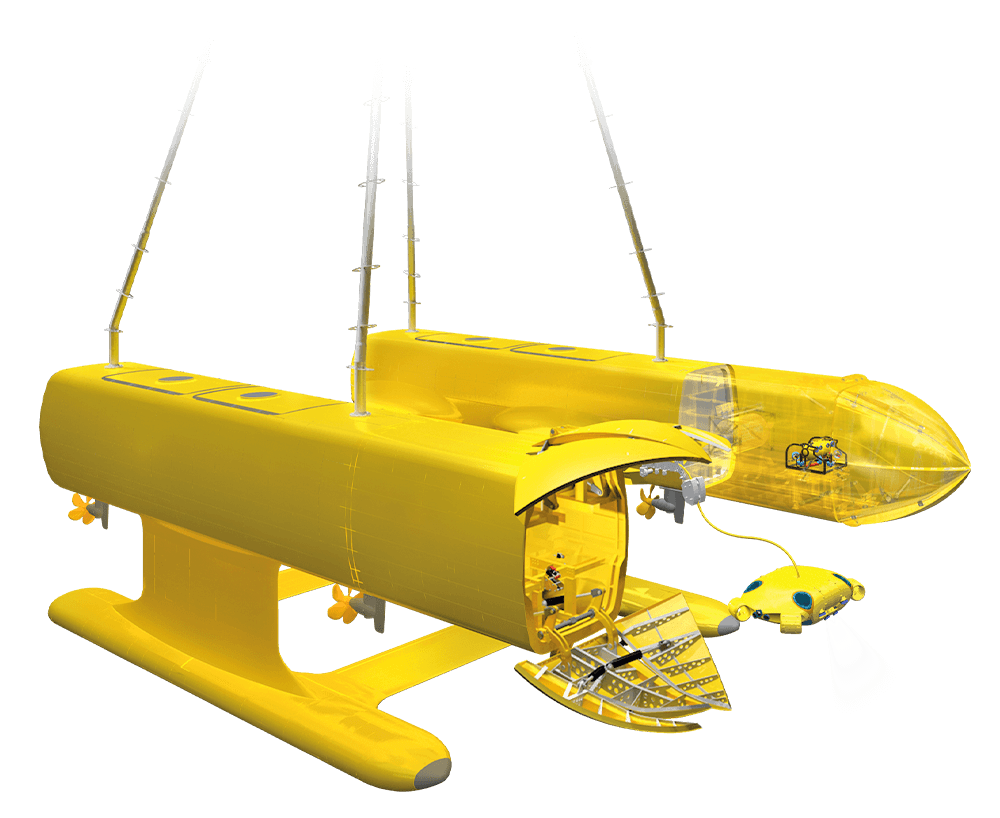

MCS’s strategic planning and resource management led to effective solutions. By deploying the Minispector® from a supply boat, the dependency on a DP vessel was bypassed, thus cutting costs. The Minispector®, fitted with multiple thrusters, offered enhanced control and stability.

The Minispector®, equipped with seven vertical and horizontal thrusters, provided full control, stability, and maneuverability. Its state-of-the-art imaging package enabled the accurate location of the pipeline’s stinger end, followed by the tracking of the 6” pipeline to the seabed, revealing the laying curve and touchdown point. The Minispector® also visually inspected the pipeline, detecting any areas of free span or instances where the pipe unintentionally rested on the seabed.

Outcomes

Efficiency, Cost Savings, and Enhanced Operations

The Minispector®’s deployment brought forth several significant results for both the client and MCS:

- Accurate Pipeline Monitoring: The client could accurately monitor and inspect the pipeline, ensuring its alignment within the theoretical corridor and compliance with project standards.

- Proactive Obstacle Detection: Minispector®’s advanced technology enabled the early detection of unexpected obstacles, including areas of free span or instances where the pipeline unintentionally rested on the seabed. By identifying these obstacles in real-time, the client was able to take immediate corrective measures, minimizing operational risks and preventing costly delays.

- Comprehensive Integrity Verification: The Minispector®’s imaging package facilitated a thorough inspection of the pipeline As-Laid, ensuring its integrity and quality. By verifying the pipeline’s condition during the laying process, our client gained valuable insights and mitigated potential risks.

- Cost Savings and Efficiency: By utilizing Minispector® and launching it from a supply boat, the client achieved significant cost savings. This innovative approach eliminated the need for a DP vessel, reducing monitoring costs by up to 90%.

In summary, the client’s adept use of Minispector® for their 6” touchdown monitoring survey stands as a testament to MCS’s commitment to offering efficient solutions. MCS’s approach in this project underscores its role in refining practices within the global energy and marine domains.