Leveraging Photo Realistic 3D Cloud (PRC) for Efficient and Cost-Effective Inspection of Offshore Structures

Project Overview

Ensuring operational integrity and promoting operational excellence.

In the fast-evolving landscape of the global energy and marine industries, innovative solutions are crucial for maintaining a competitive edge. This study illustrates MCS Group's collaboration with a top-tier production company in the Gulf region to modernize its inspection process. Faced with the task of inspecting over 250 offshore structures, the client selected 26 crucial structures needing thorough and efficient inspection data at a reasonable cost.

Challenges

Navigating the complexity of inspecting aging structures.

The client’s portfolio of structures posed a unique challenge. A significant portion of the client’s structures had been in service for over three decades, introducing complications for inspection and mitigation. To guarantee operational safety and mitigate risks, the client aimed to digitize their inspection data. Additionally, they required precise as-built drawings for their older platforms.

Solution

Streamlining Inspection Data with MCS Photo Realistic 3D Cloud (PRC)

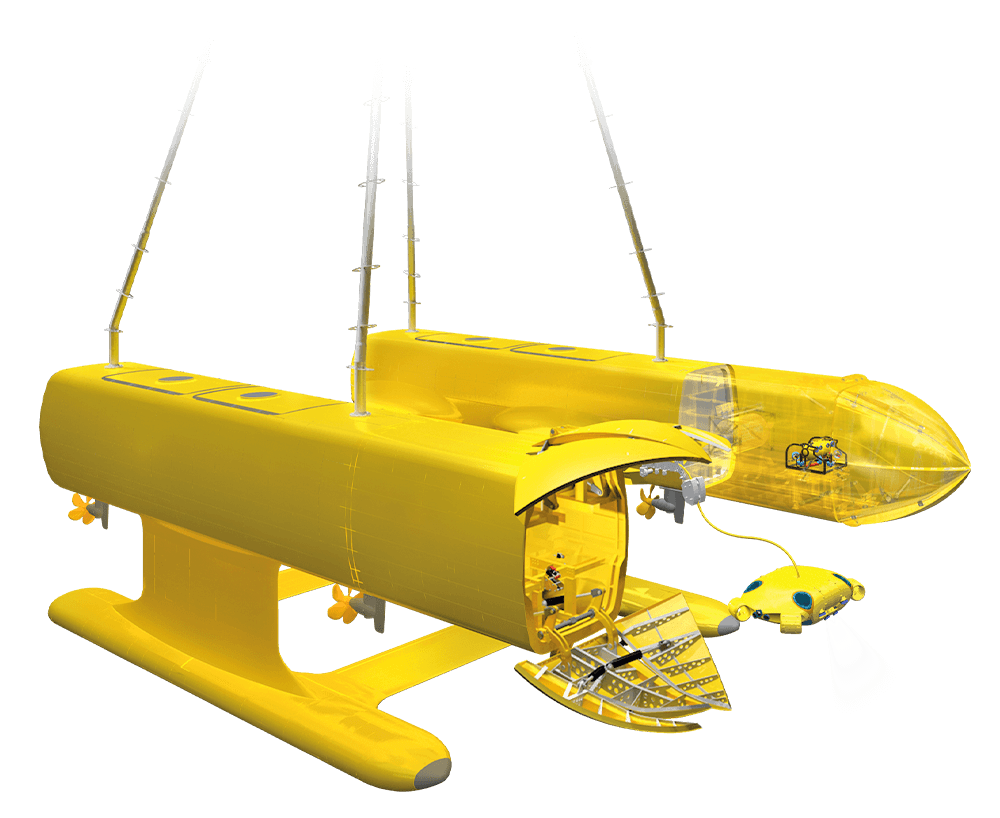

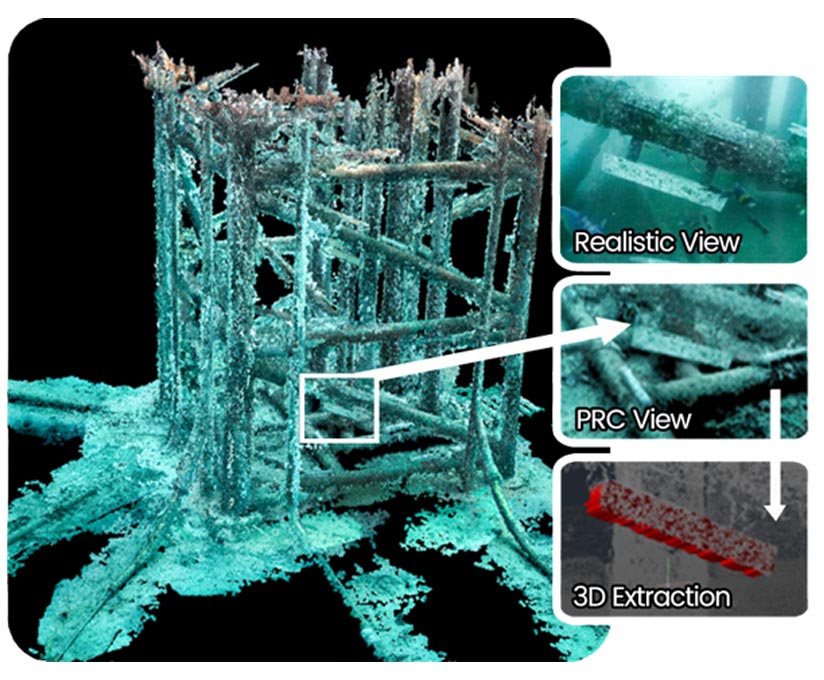

To meet the client’s needs, MCS Group introduced its state-of-the-art Photo Realistic 3D Cloud (PRC) technology, supplemented with ROVs. A pilot project commenced, focusing first on inspecting a well-head tower using PRC technology through an ROV. The resultant 3D model’s accuracy met high standards and delivered exceptional results.

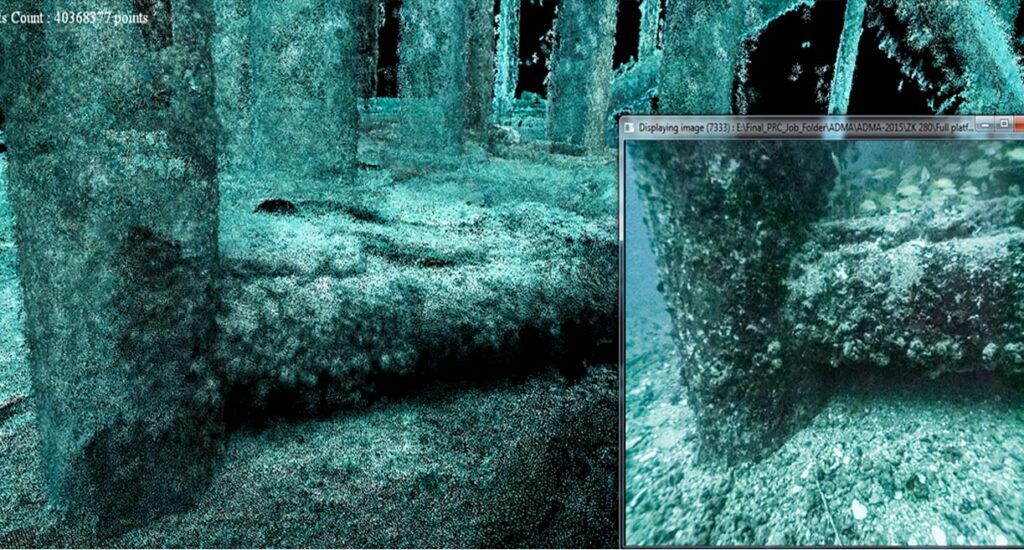

Motivated by the positive feedback, the client adopted the MCS PRC technology to capture as-built images of their structures. This step enabled them to detect damages, defects, and potential threats, thereby guiding their future integrity planning. The PRC technology, despite the structures’ age, offered the needed adaptability and precision, ensuring cutting-edge inspection data.

Outcomes

Efficiency, Cost Savings, and Comprehensive Inspection

The decision to leverage MCS PRC technology for their inspection needs yielded remarkable outcomes for the client:

- Cost-Effective Efficiency: The PRC technology enabled a more efficient inspection process, resulting in substantial time and cost savings. This optimized method ensured detailed inspection data for their 26 key structures.

- Precision: The PRC provided exact as-built images, furnishing the client with updated documentation vital for maintenance, planning, and compliance. This data’s high accuracy empowered the client to make well-informed decisions.

- Enhanced Safety: Utilizing ROVs eliminated the need for divers, reducing potential risks linked with manual inspections. This ensured the safety of the personnel and mitigated potential hazards tied to offshore structure access.

- Proactive Integrity Planning: With access to precise inspection data, the client was able to preemptively address any damage, defects, or deterioration in their structures. This approach minimized the chances of structural problems, unexpected downtimes, and expensive repairs, ensuring operational excellence.

MCS Group is committed to fostering innovative solutions. This study underscores our dedication to transforming the energy and marine industries with our advanced technology offerings. Our pioneering technology propels us to facilitate transformative results for our clients, ultimately shaping a sustainable future for the industry.