Maximize Efficiency and Reliability with MiniSpector® for Underwater pipeline inspection.

Project Overview

Transforming Pipeline Inspection

This case study outlines how an operator in the Gulf area effectively utilized MCS Group's MiniSpector® technology for underwater external inspections. The focus was on maintaining the integrity and safety of pipelines, PLEM, and SPM chains and flexibles in the Gulf area, identifying any potential risks for ongoing operations.

Challenges

Breaking Through Barriers

Our client faced several unique challenges during this project:

- Shallow Water: The waters’ depth demanded a solution capable of navigating and functioning efficiently in shallow environments.

- Non-DP Vessel Constraints: The inspection needed to be conducted from a non-DP vessel, which introduced additional challenges in terms of stability and maneuverability.

- Launching System for ROV: A suitable Launching system was essential to ensure the safe deployment and retrieval of the MiniSpector® ROV.

- ROV Capabilities: The ROV needed to support specific sensors to ensure a comprehensive inspection.

Solution

Overcoming Challenges with Precision and Efficiency

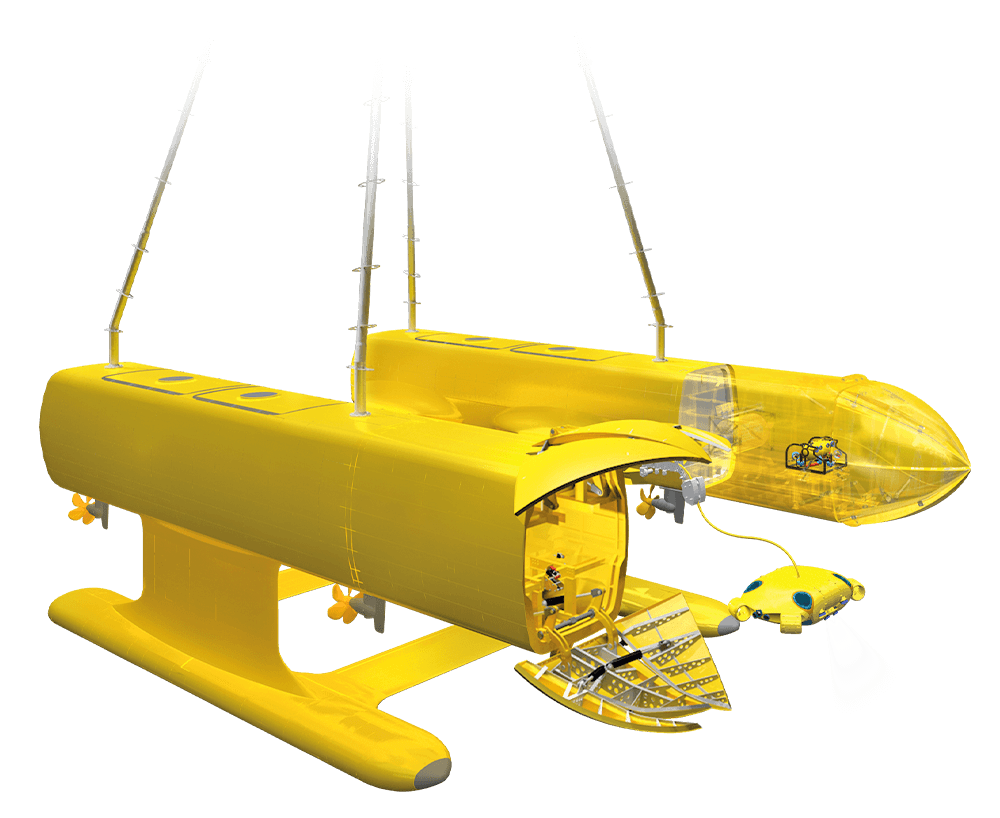

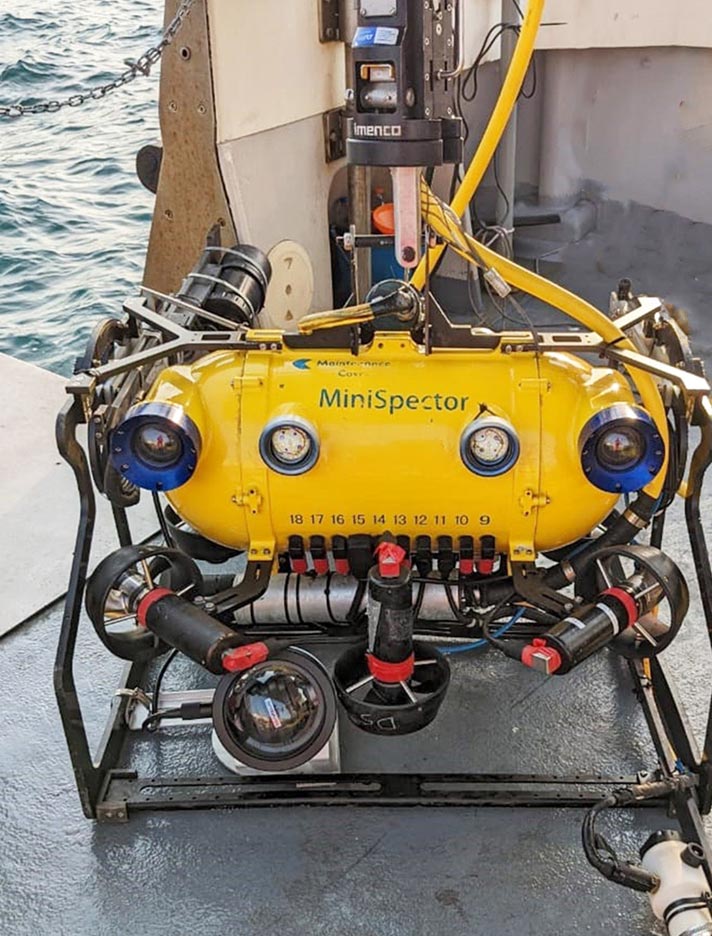

MCS Group provided a comprehensive solution, utilizing MiniSpector®, a cutting-edge underwater inspection technology. The solution included the following key components:

- Small Low Draft Boat: MCS identified and utilized a small low draft boat to overcome the challenges posed by shallow water conditions.

- MCS MiniSpector® Installation: MiniSpector® was securely installed on the boat’s deck, serving as a stable and easily accessible platform for inspection tasks and operations.

- Sensor and Camera Integration: The MiniSpector® system integrated the necessary sensors and cameras, equipping our client with the ability to capture high-quality data and imagery during the inspection.

- Document Management: The MCS Group team efficiently processed required documents and approvals, ensuring smooth project execution.

Outcomes

Efficiency, Cost Savings, and Enhanced Integrity

The deployment of the MiniSpector® system bore several tangible benefits:

- Pipeline and PLEM Inspection: MiniSpector® enabled accurate visual inspections and UT measurements for PLEM, aiding precise condition assessment.

- Damage Identification: MiniSpector’s sensors and cameras allowed the operator to quickly identify and locate areas of damage, ensuring prompt remediation actions.

- Areas of Free Span: The MiniSpector system enabled the identification and accurate location of areas of free span, facilitating timely corrective actions to maintain the structural integrity of the assets.

- Anodes Assessment: MiniSpector® facilitated a comprehensive condition assessment of the sacrificial anodes fitted along the pipelines, PLEM, and SPM, ensuring optimal corrosion protection.

- SPM and Hose Inspection: MiniSpector® conducted visual checks on the SPM and underwater hose, and accurately measured the CP potential. This inspection enabled the client to proactively address any issues.

The collaboration between the industry leader and MCS Group led to enriched underwater inspection outcomes. By leveraging MiniSpector, our client maximized efficiency and reliability. MiniSpector® minimized inspection time, reduced costs, and ensured accurate data gathering for a thorough assessment of pipeline condition, PLEM, SPM chains & flexibles. MCS Group continues to focus on delivering solutions that enhance efficiency, safety, and sustainability across the energy and marine industries. For more information on how our advanced technologies can benefit your operations, please contact us.