Project Overview

Within the West Delta Deep Marine (WDDM) Phase 10 and Phase 11 EPIC projects, executed by MCS Group and Petroleum Marine Services (PMS) for Burullus Gas Company, (a JV between Shell and Egyptian General Petroleum Corporation (EGPC)), six new subsea wells were successfully integrated into the existing offshore infrastructure.

Precise subsea measurements were delivered using MCS’s Photo Realistic 3D Cloud (PRC) technology, which played a critical role in achieving the project’s objectives.

The scope of the PRC technology in the project included:

- Jumper metrology to ensure accurate measurements and installation of 8 subsea jumpers to connect the six wells to the existing subsea infrastructure.

- Umbilical Installation Surveys to confirm precise positioning relative to existing infrastructure.

- Pre-Engineering and As-built Surveys to provide detailed 3D models of the subsea environment and installed structures.

Key Considerations

- Complex Subsea Layout: Integrating six new wells into the existing subsea network at depths ranging from 450m to 660m demanded precise planning to avoid clashes with the existing infrastructure.

- Accuracy in Jumper Installation: The pre-engineering, fabrication & installation of eight jumpers, each measuring up to 29 meters, required millimeter-level accuracy to ensure smooth connections between the wells and the subsea infrastructure.

- Umbilical Laying: During Phase 10, ensuring the precise positioning of the 5 km and 2 km umbilical in relation to the existing infrastructure.

- Subsea Environment Challenges: The complex subsea environment needed the use of 3D visualization to identify potential misalignments and guide immediate corrections.

- Verification and Integrity: Pre-engineering and as-built surveys were essential to confirm alignment and asset integrity.

Solution

The deployment of Photo Realistic 3D Cloud (PRC) technology ensured the successful delivery of the West Delta Deep Marine (WDDM) Gas Field Development Project across major phases such as the umbilical laying and jumper fabrication and installation.

The operation sequence was divided into four key stages: Umbilical Laying Assistance, Jumper Pre-Engineering Survey, Metrology, and As-Built Survey.

1. Umbilical Laying Assistance In Phase 10

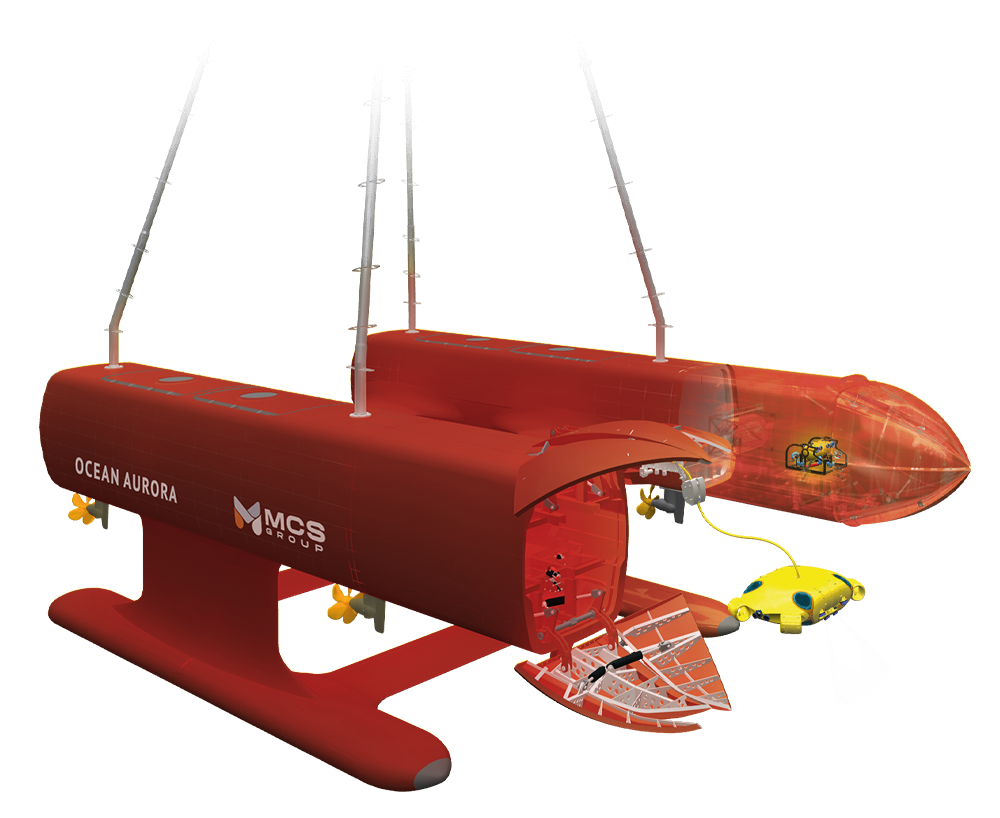

A DeepTech work-class ROV (Triton XLS 43) equipped with MCS PRC cameras was deployed to assist in the 5km & 2km umbilical laying process.

The PRC system was utilized to accurately position the Mudmat relative to existing subsea structures, such as the Umbilical Termination Assembly (UTA).

This enabled the onboard survey team to determine the precise start & end positions of the 4x Mudmat, ensuring accurate alignment during the umbilical laying operation without any interference with nearby subsea infrastructure.

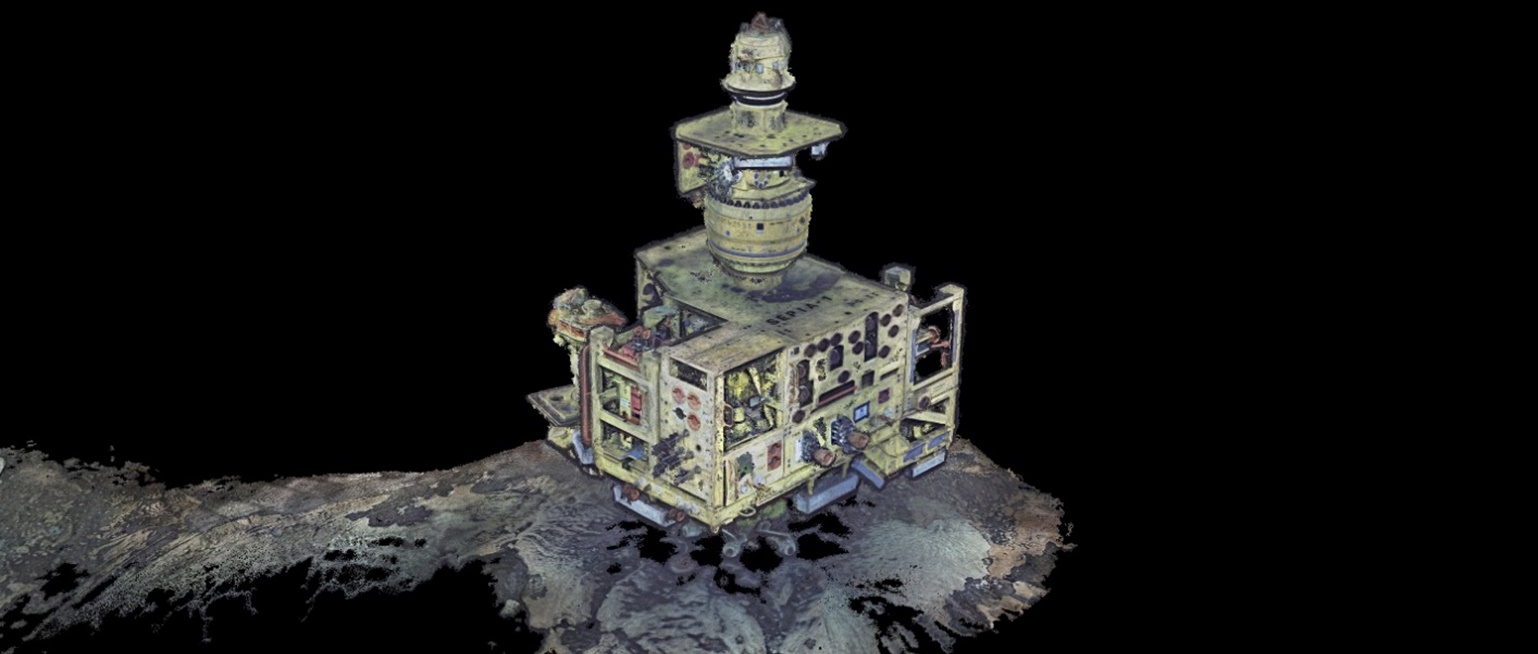

Figure 1: UTA (Umbilical Termination Assembly) - PRC 3D point cloud during the umbilical laying

Figure 2: UTA (Umbilical Termination Assembly) - PRC 3D point cloud during the umbilical laying

2. Pre-Engineering Survey

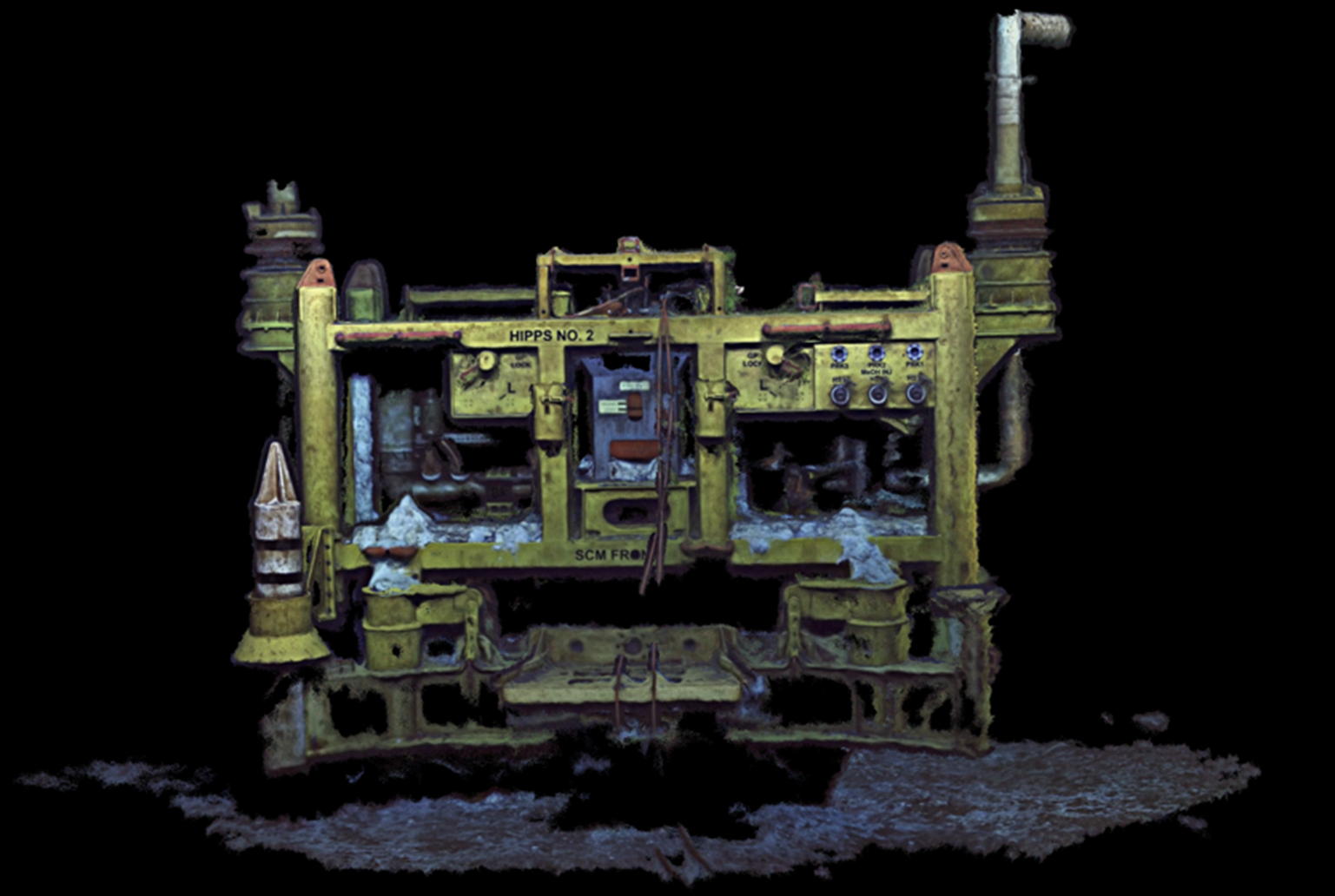

The PRC system was deployed to perform a detailed pre-engineering survey for jumper fabrication and installation.

It generated a 3D point cloud model with precise measurements, offering a comprehensive and detailed representation of the subsea environment.

This model included all critical distances and inclinations of subsea structures, such as PLETs, UTAs,, and X-Trees.

Figure 3: PLET - PRC 3D Point Cloud during the Pre-Engineering Survey.

Figure 4: X-Tree - PRC 3D Point Cloud during the Pre-Engineering Survey.

Figure 5: TSB - PRC 3D Point Cloud during the Pre-Engineering Survey.

Figure 6: HIPPS - PRC 3D Point Cloud during the Pre-Engineering Survey.

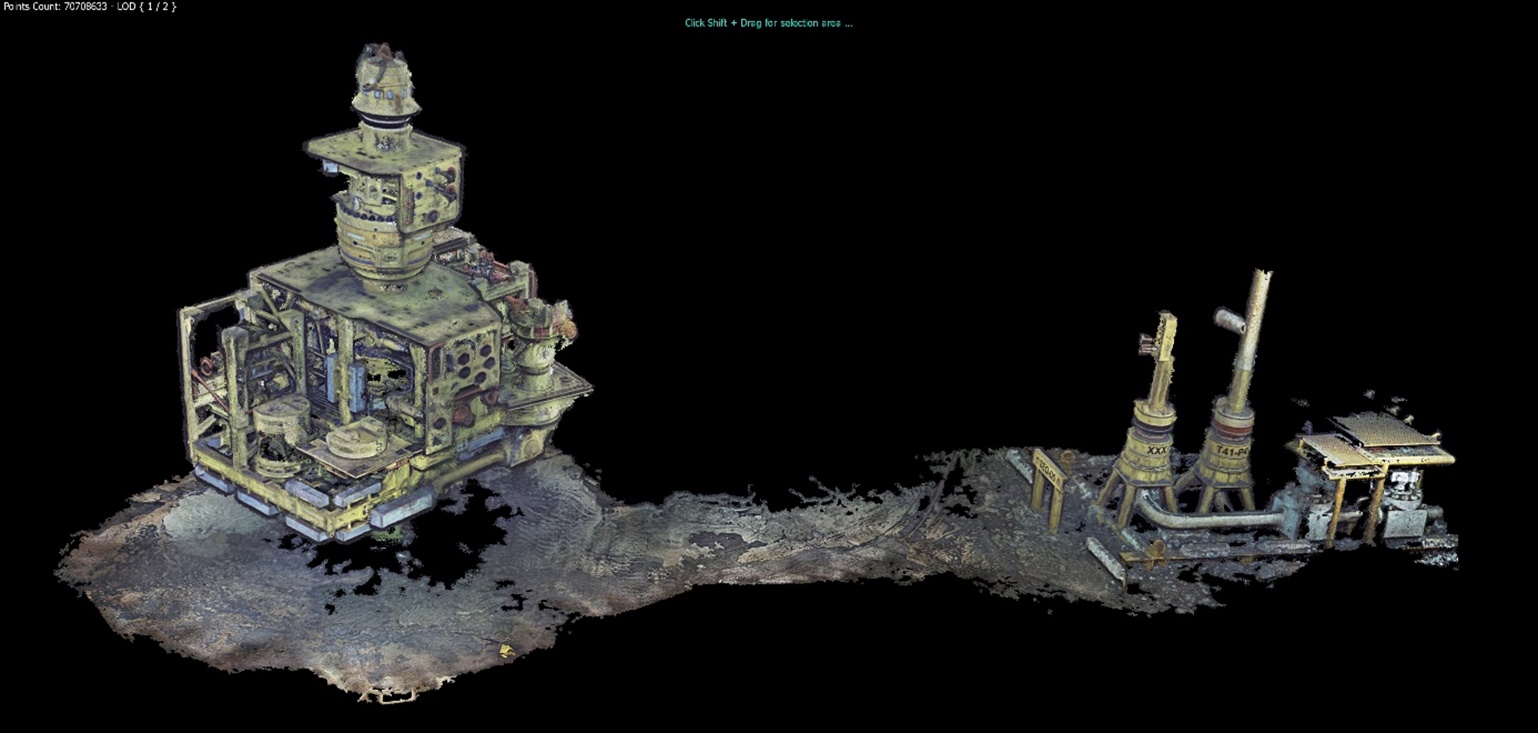

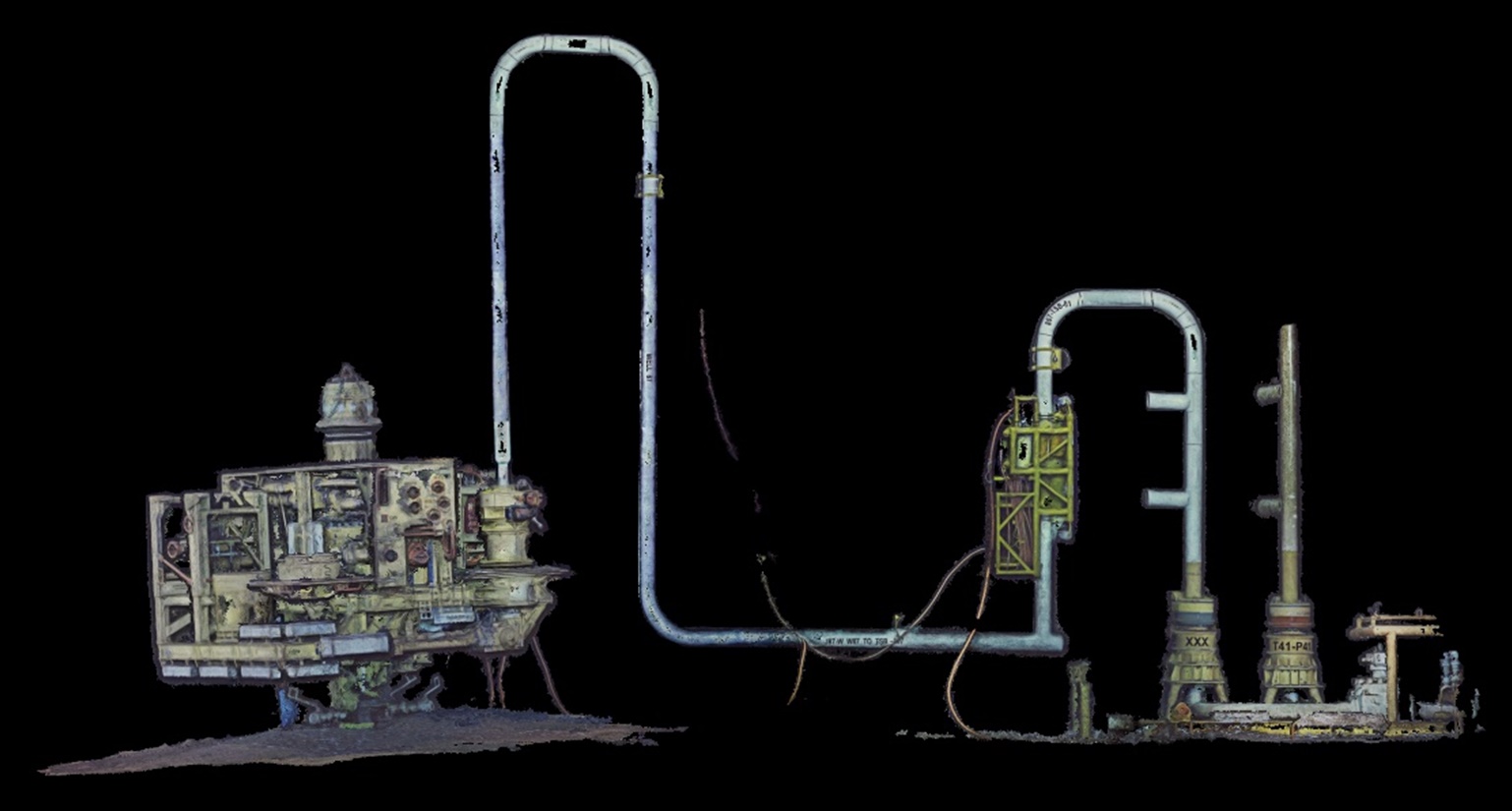

Figure 7: Pre-Engineering PRC 3D Point Cloud Result – General Overview.

3. Jumper Metrology and Fabrication

• Data Collection and Modeling

The detailed data gathered during the Pre-Installation Survey was processed by the MCS Inspection and Survey teams using PRC software and MCS Computer Vision technology.

This enabled the creation of 3D point cloud models with highly accurate measurements.These models were essential for the MCS team to determine jumper lengths, angles, and connection points, forming the foundation for precise jumper designs.

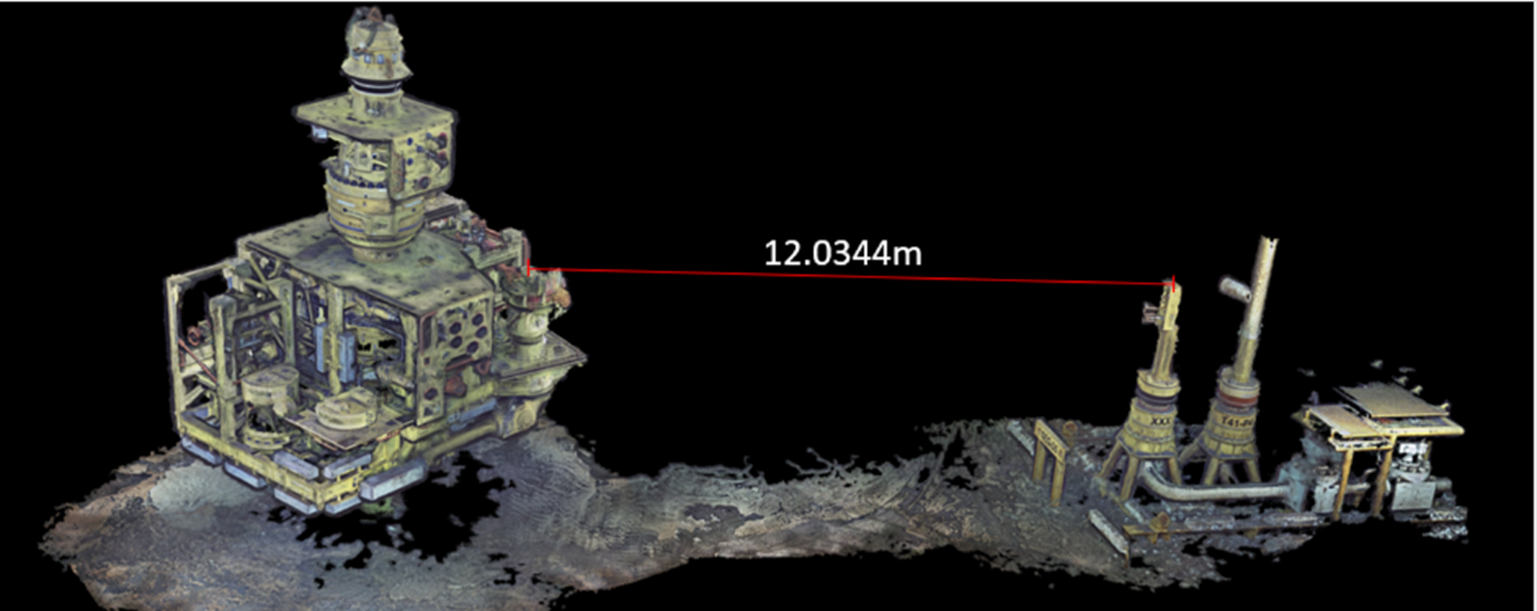

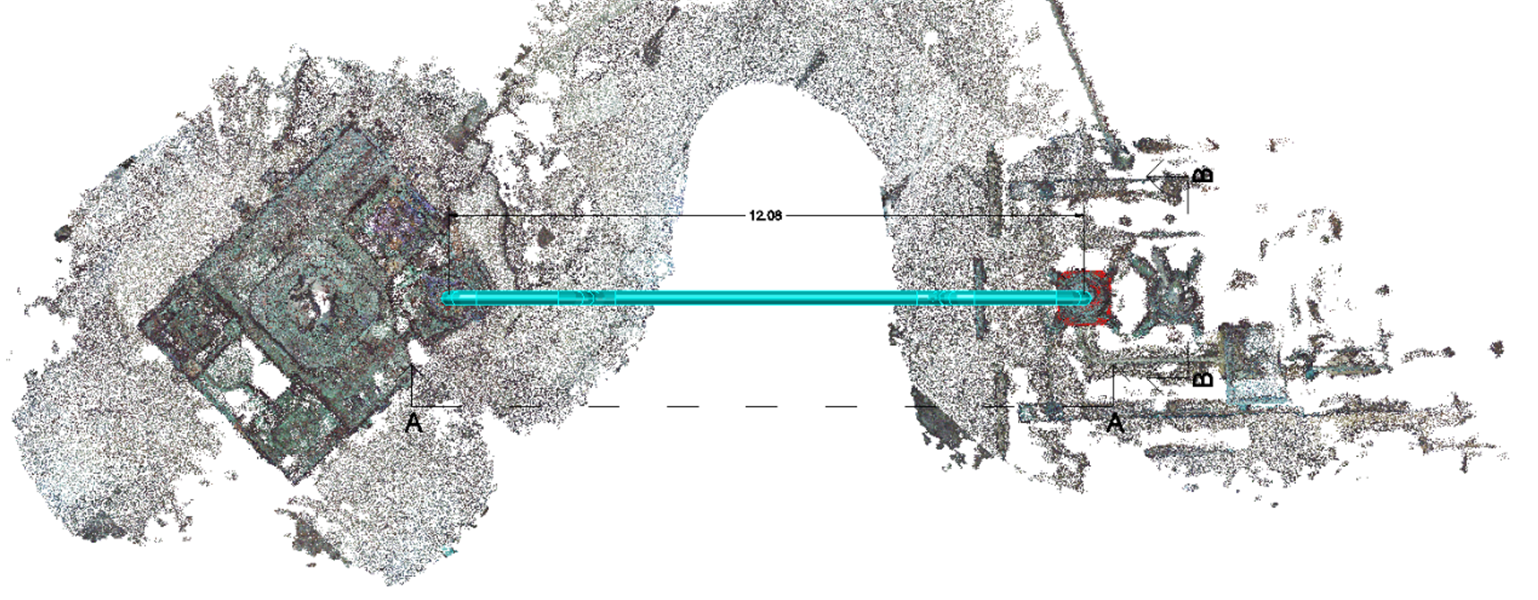

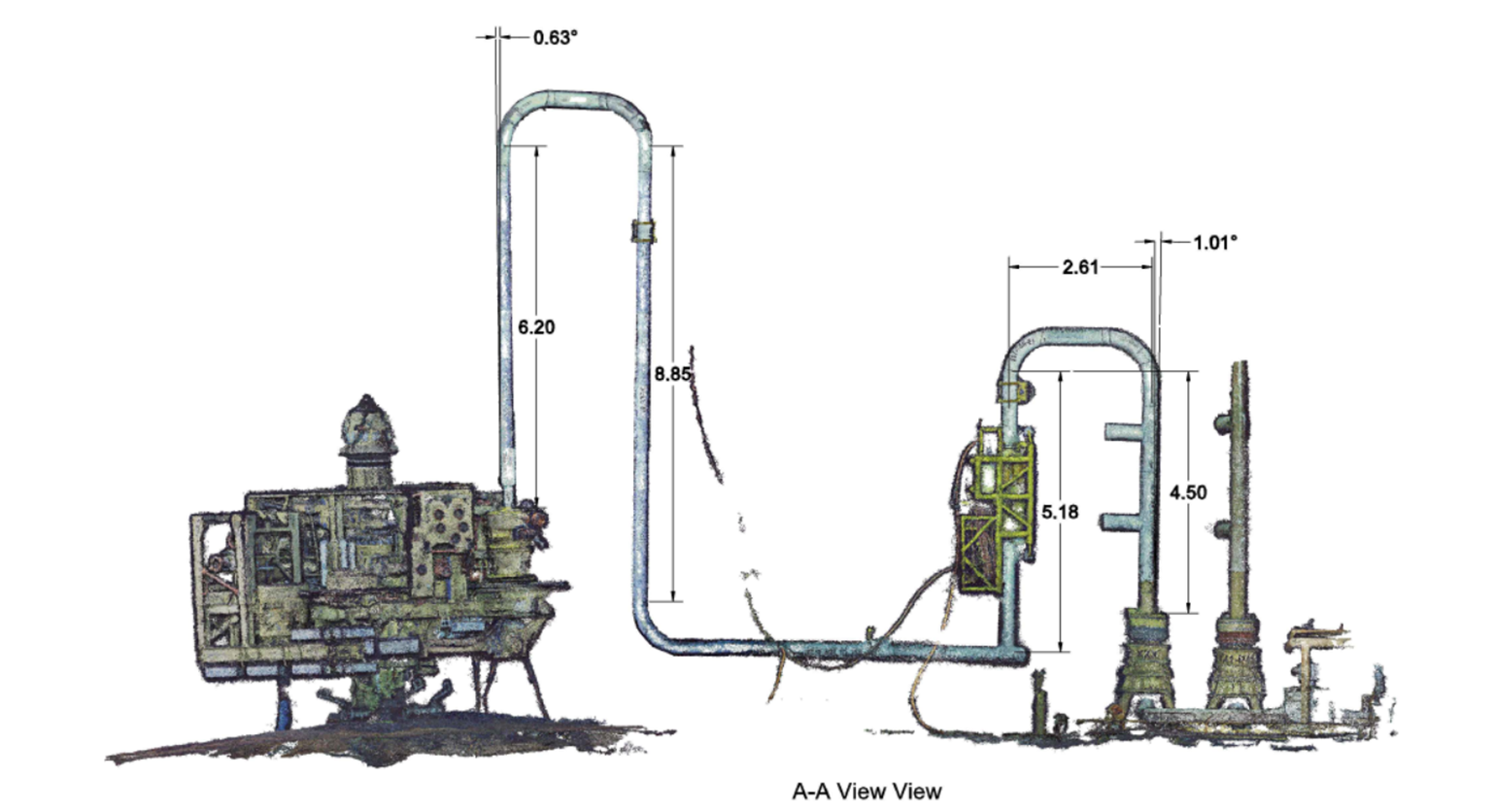

Figure 8: Jumper Metrology.

Figure 9: General Measurements for Jumper.

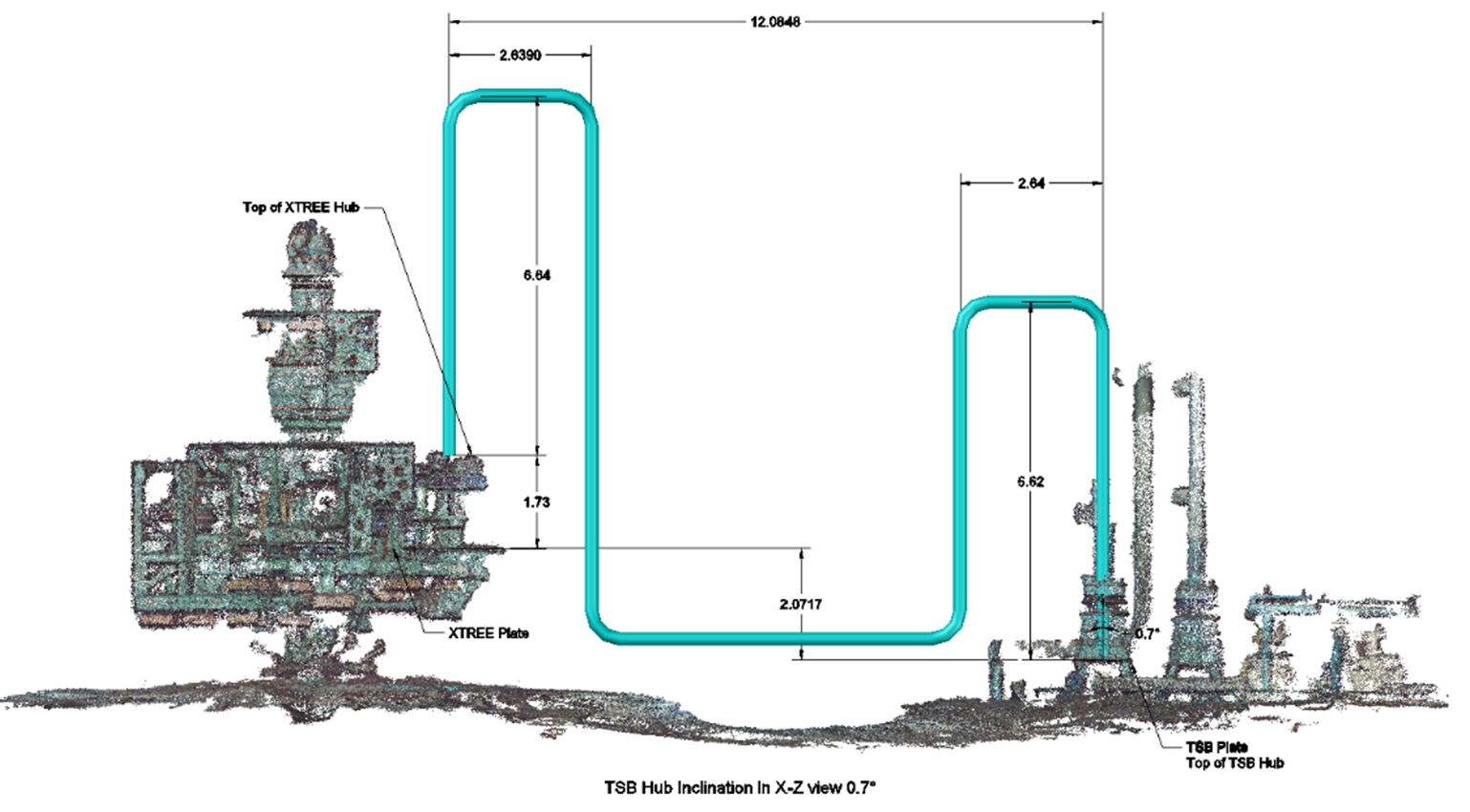

Figure 10: TSB Hub Inclination Y-Z View - Angular Measurement.

Figure 11: TSB Hub Inclination X-Z View – Relative measurements.

• Jumper Design, Fabrication & Installation

With this comprehensive data, the MCS team validated the jumper designs, which were developed by the Engineering team, ensuring alignment with the existing infrastructure.

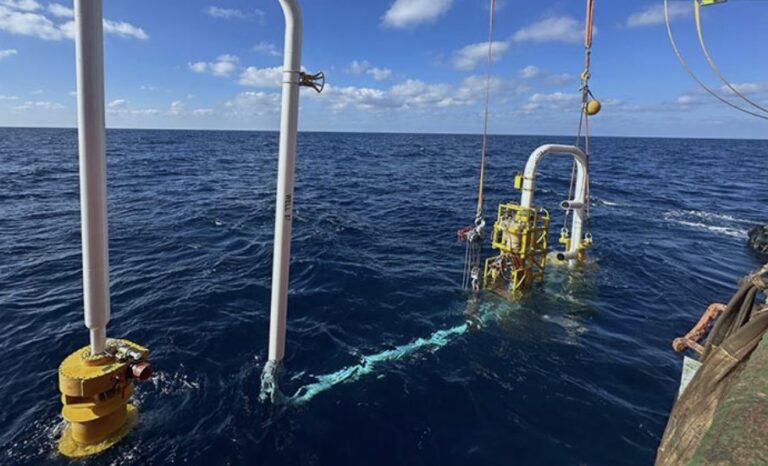

As a result, the jumpers were produced to fit with the subsea structures, enabling flawless installation, which was conducted by DeepTech, part of the MCS Group, using their Work Class ROVs.

Figure 12: Jumper Installation Operations Post-Fabrication

Figure 13: As-Built Survey Conducted by DeepTech Work-class ROV and MCS PRC Cameras

4. As-Built Survey

• Data Collection and Modeling

Once the jumpers were installed, a post-installation Survey was conducted to verify the positioning and integrity of the installed jumpers.

Using precise measurements from the PRC system, the subsea teams utilized the survey data in jumper stress analysis to assess the structural performance after installation.

The survey confirmed compliance with project requirements and ensured the long-term integrity of the subsea system.

Figure 14: As-Built PRC 3D Point Cloud Result: General Overview After Jumper Installation

Figure 15: As-Built PRC 3D Point Cloud model: Measurements After Jumper Installation

Outcomes

The deployment of PRC technology in WDDM Phase 10 and Phase 11 resulted in significant improvements across multiple areas and key outcomes included:

- Reduced Cost and Time:

PRC technology reduced both operational costs and time by completing structure surveys within 3–5 hours per structure, compared to the extended mobilization, demobilization, and survey durations required by other alternative methods such as LBL, thereby minimizing project downtime and resource usage. - Improved Accuracy:

MCS PRC technology delivered millimeter accuracy, ensuring precise jumper fabrication, smooth installation, accurate alignment of subsea structures, and reliable data for advanced analyses, such as stress assessment after jumper installation. - Comprehensive Insights:

The 3D models generated by PRC provided a complete and detailed representation of subsea structures, allowing for precise measurements and visualizations, and enabling teams to address additional requirements beyond the pre-defined scope.