MiniSpector® Empowering Offshore Platforms Construction with Fast and Accurate Inspections

Project Overview

Streamlining Offshore Platform Inspection with MiniSpector®

A notable energy and marine sector entity in Egypt initiated a construction project demanding high-grade expertise and meticulous inspection methods to ensure adherence to industry standards. Recognizing the essence of expedient and precise inspections, the client employed MiniSpector®, MCS Group's groundbreaking technology, aiming to confront their construction project's inherent challenges.

Challenges

Distinct Subsea Obstacles and Limited Resources

The operator was faced with several challenges to overcome in order to perform the construction work on the eight offshore platforms. These challenges included:

- Helipad construction and modification on six platforms: The client’s project involved the construction and modification of helipads on six platforms. These modifications necessitated meticulous inspection methodologies to ensure structural integrity, compliance with safety regulations, and optimal functionality.

- Inaccessible two flare platforms that cannot be approached by a vessel: The presence of inaccessible flare platforms, which couldn’t be approached by traditional vessels, posed a significant challenge. A solution that enabled inspection and data collection in these difficult-to-reach areas was imperative.

- Lack of Available DP2 Vessel: The unavailability of a Dynamic Positioning Class 2 (DP2) vessel for inspection work further exacerbated the challenges faced by the operator, requiring an alternative approach that could match the precision and reliability of conventional methods.

- Need for as-built drawings for older platforms: The client required accurate as-built drawings for older platforms to gain a comprehensive understanding of existing conditions and facilitate necessary construction modifications.

Solution

Pioneering Platform-Based Inspection in Egypt with MiniSpector®

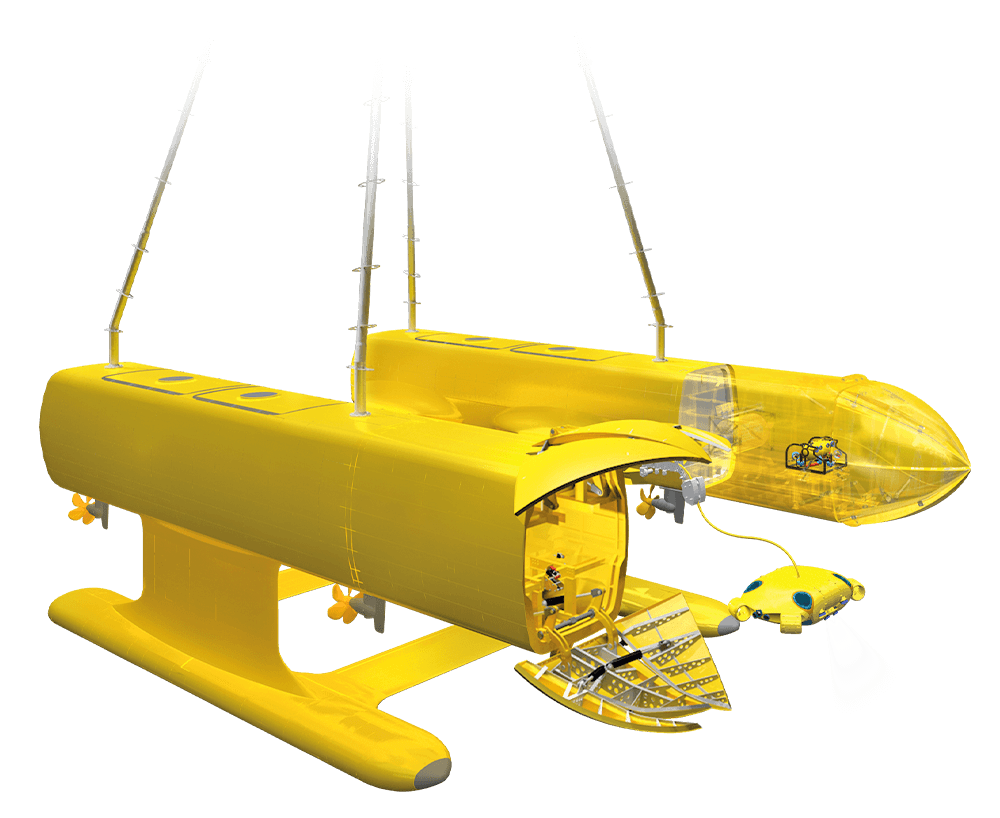

MiniSpector® transformed the operator’s construction project with its advanced inspection features that facilitated comprehensive analysis and assessment. Here’s a closer look at how it redefined the inspection process:

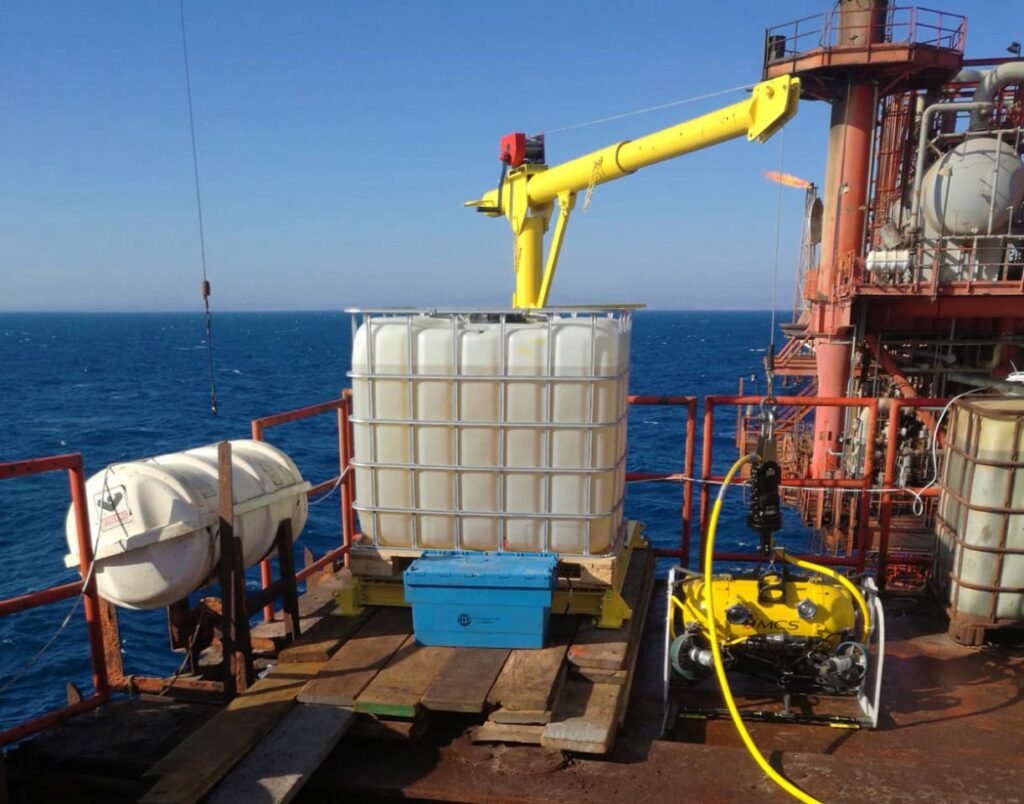

- Platform Deck Deployment of MiniSpector®:

MiniSpector’s launch from the platform deck enabled efficient inspections, eliminating the need for conventional DP2 vessels. This streamlined process significantly reduced costs and minimized project downtime. - Extended Inspection Reach with the 600m Umbilical Cable:

MiniSpector’s 600m umbilical cable allowed for inspections on remote flare platforms, including those as distant as 250m from the launch point. This extended reach facilitated access to vital data from areas that were previously hard to access. - High Stability of MiniSpector® in Challenging Conditions:

Even amidst high currents, MiniSpector® maintained its stability and agility, ensuring precise data collection in challenging subsea conditions. - Diverse Inspection Capabilities:

Thanks to its versatile design, MiniSpector® supported a range of inspection tasks such as General Visual Inspection (GVI), Cathodic Protection (CP), Ultrasonic Testing (UT), and Full Matrix Capture (FMD). This versatility granted a comprehensive view of the platform’s condition. - Advanced Monitoring with MCS Structure Commander Integration:

Pairing with the MCS Structure Commander enabled enhanced inspection and superior condition monitoring. - Producing Precise As-Built Documentation with PRC:

The inclusion of MiniSpector’s Photo Realistic 3D Cloud (PRC) feature was instrumental in generating detailed as-built diagrams, equipping the client with crucial records for subsequent construction phases.

Outcomes

Precision, Cost-Effectiveness, and Comprehensive Inspection

The client experienced remarkable outcomes from their collaboration with MCS Group and the utilization of the MiniSpector®:

- Time Efficiency: MiniSpector’s agility and advanced capabilities allowed for a streamlined and efficient inspection process. With quick deployment and accurate data collection, the operator witnessed a significant improvement in the project timelines.

- Significant Cost Savings: the client benefited from cost savings of up to 80% compared to conventional inspection methods, thanks to the MiniSpector® as a platform-based inspection solution. By eliminating the need for a DP vessel, our client was able to optimize their budget while still ensuring comprehensive inspections.

- Accurate As-Built Drawings: The MiniSpector® integration of the MCS solution, Photo Realistic 3D Cloud (PRC), enabled the client to generate precise as-built drawings for the older platforms. This detailed documentation provided invaluable insights for project planning, execution, and ongoing maintenance activities.

- Access to Inaccessible Platforms: Leveraging the capabilities of the MiniSpector®, the operator successfully inspected and assessed the two flare platforms that were previously inaccessible to traditional vessels. This breakthrough allowed our client to address critical maintenance and construction requirements.

- Sustainability: By utilizing the MiniSpector®, the operator further demonstrated their commitment to sustainable practices by reducing the environmental footprint.

The operator’s overall success and satisfaction with the implementation of MiniSpector underscores its transformative potential in providing efficient, green, and cost-effective solutions.