Photo Realistic 3D Cloud (PRC) transforms subsea spool piece installation

Project Overview

Advancing Subsea Spool Piece Installation in the Gulf of Suez, Egypt.

MCS Group emphasizes the importance of evolving underwater technical solutions for the energy and marine sectors. A prominent client in the Egyptian energy sector encountered challenges during the installation of nine subsea spool pieces in the Gulf of Suez. Our Photo Realistic 3D Cloud (PRC) technology significantly improved the subsea spool piece installation process for this client.

Challenges

Metrology and Installations Complexities

The client sought efficient and diver-free methods to ensure a smooth installation of subsea spool pieces and mitigate risk. Specific challenges included:

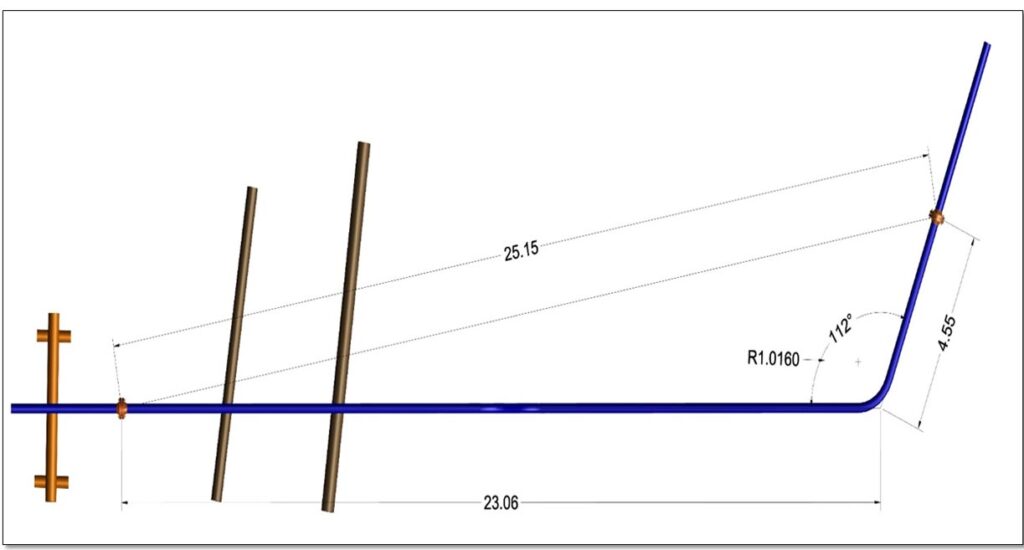

- Critical Need for Accurate Metrology: Accurate metrology was essential to ensure the subsea spool pieces were installed safely and with precision.

- Fast, Diver-less Solution Required: Our client required a fast and efficient solution that eliminated the need for human intervention underwater, reducing risk and accelerating operation speed.

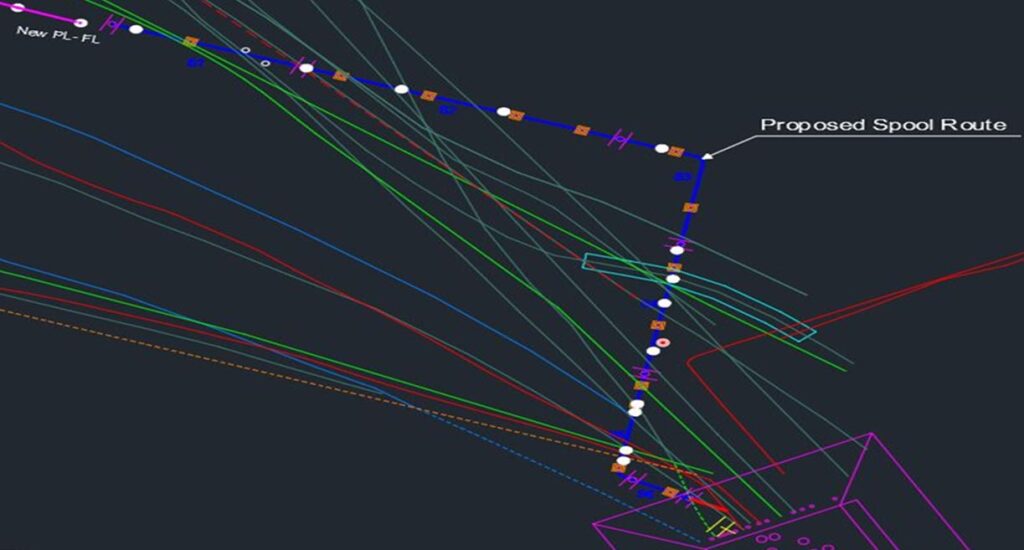

- Challenging and Diverse Range of Water Depths: The project involved a range of water depths, including 15m to 75m. This encompassed Closing Spool Metrology, Crossing and Clearance Metrology, Proposed Route Survey, As Built Survey, and Free Span Measurements.

Solution

Optimizing Technology Integration

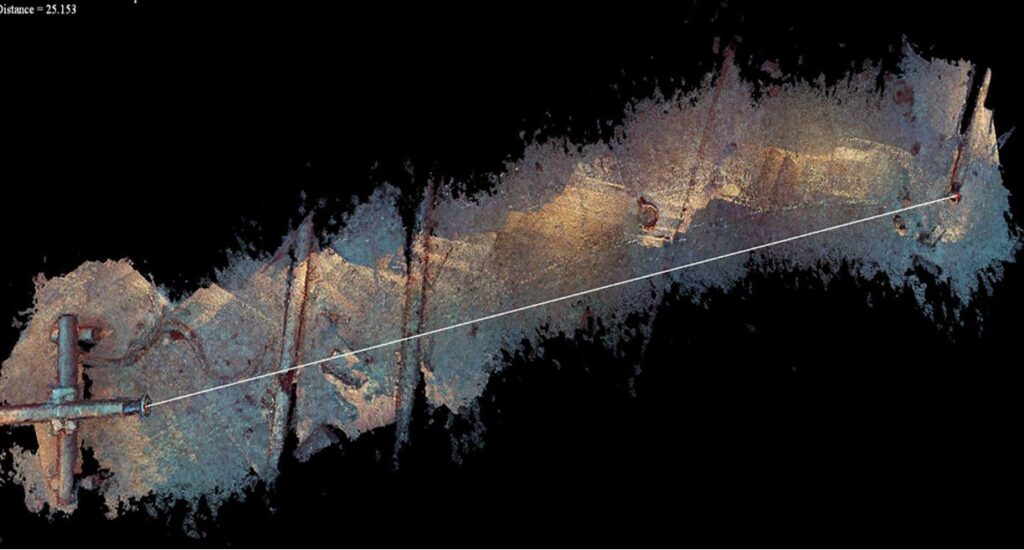

MCS’s Photo Realistic 3D Cloud (PRC) technology offered effective solutions through:

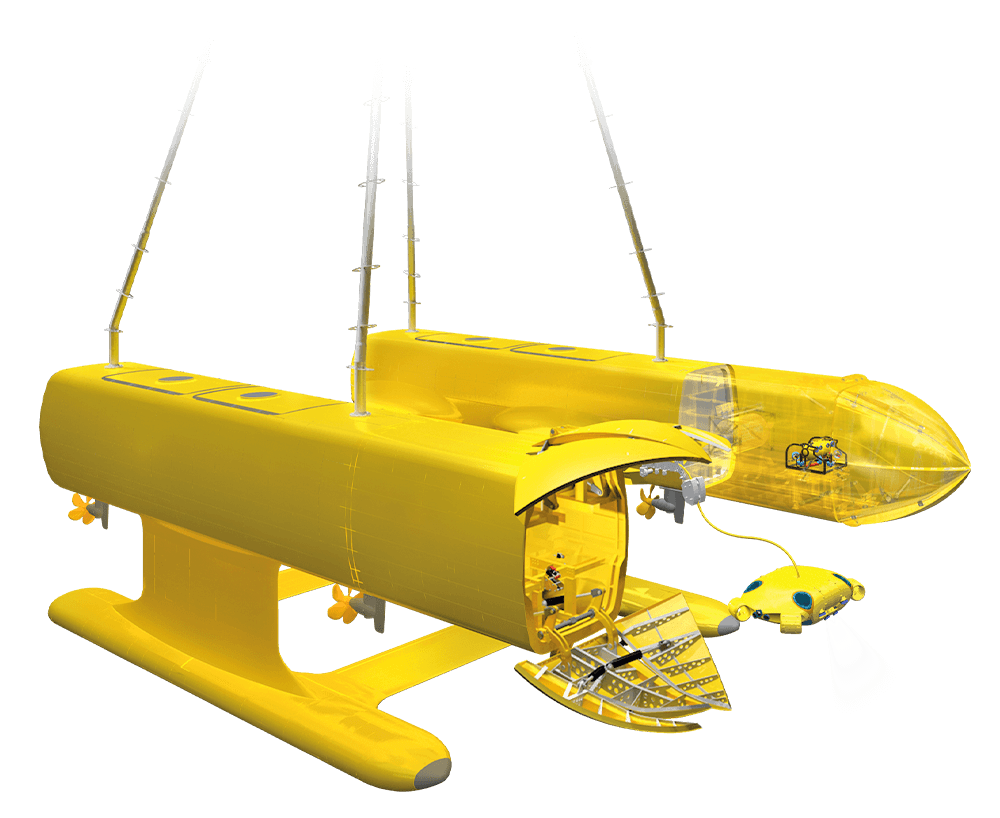

- Integration with Any ROV: Our PRC technology integrates seamlessly with any remotely operated vehicle (ROV), functioning effectively in depths up to 3000m.

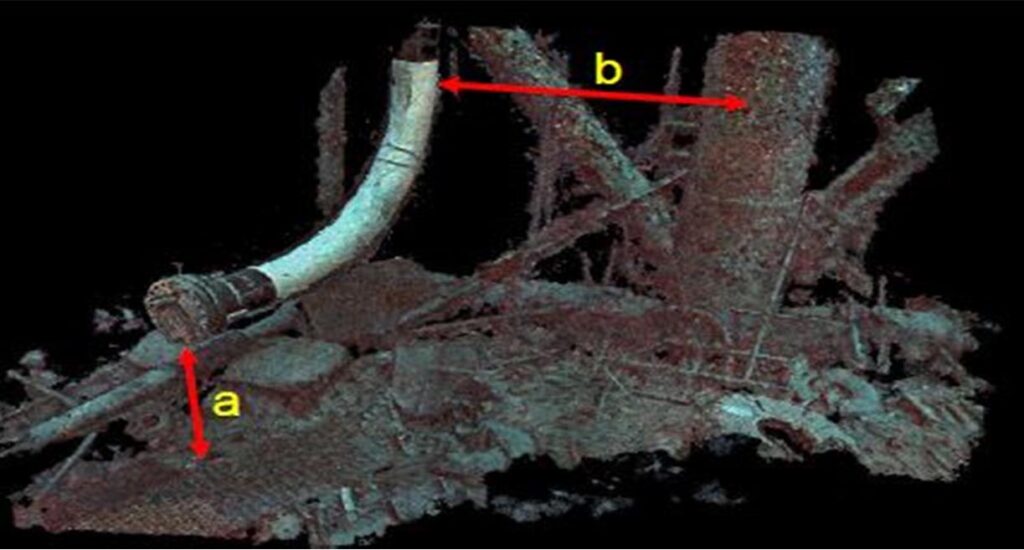

- Detailed Surveys in Complex Conditions: The PRC ensures precise data collection, even in intricate underwater scenarios with multiple pipeline crossings and other obstacles.

- Through 3D Blueprint: Our method offers a detailed, as-installed 3D model of the subsea structures, beneficial for future checks and interventions.

- Comprehensive 3D Model for Future Interventions: Our solution provides a comprehensive, as-built model of subsea installations and the surrounding area, beneficial for future intervention and inspection works.

Outcomes

Operational Improvements and Cost Benefits

Our PRC solution delivered significant outcomes for our client:

- Unparalleled Accuracy and Reduced Risk: The PRC’s precise metrology ensured that the subsea spool pieces were installed with unrivaled accuracy. Our client experienced a reduced risk of operational issues and structural instability, guaranteeing the integrity of their underwater infrastructure.

- Time and Cost Efficiency: By adopting the PRC solution, our client achieved significant time savings in the installation of the subsea spool pieces. These time savings translated into cost savings and increased the project’s overall profitability.

- Safety and Minimal Environmental Footprint: Through the deployment of PRC, our client was able to eliminate the need for human divers, enhancing safety and minimizing the environmental impact of the installation.

- Positioned as Innovators: Collaborating with MCS Group and integrating the PRC technology, the client has reinforced their leadership stance in Egypt’s energy sector. Their investment in innovative solutions emphasizes a progressive and visionary approach.

At MCS Group, we are driven by our vision to transform the global energy and marine sectors through our proprietary technology. We continue to push boundaries, finding innovative solutions to tackle industry challenges and contribute to a sustainable future.