Utilize Photo Realistic 3D Cloud (PRC) to Enhance Subsea Pipeline Construction for Unprecedented Project

Project Overview

Streamlining Subsea Pipeline Projects with Advanced Technology

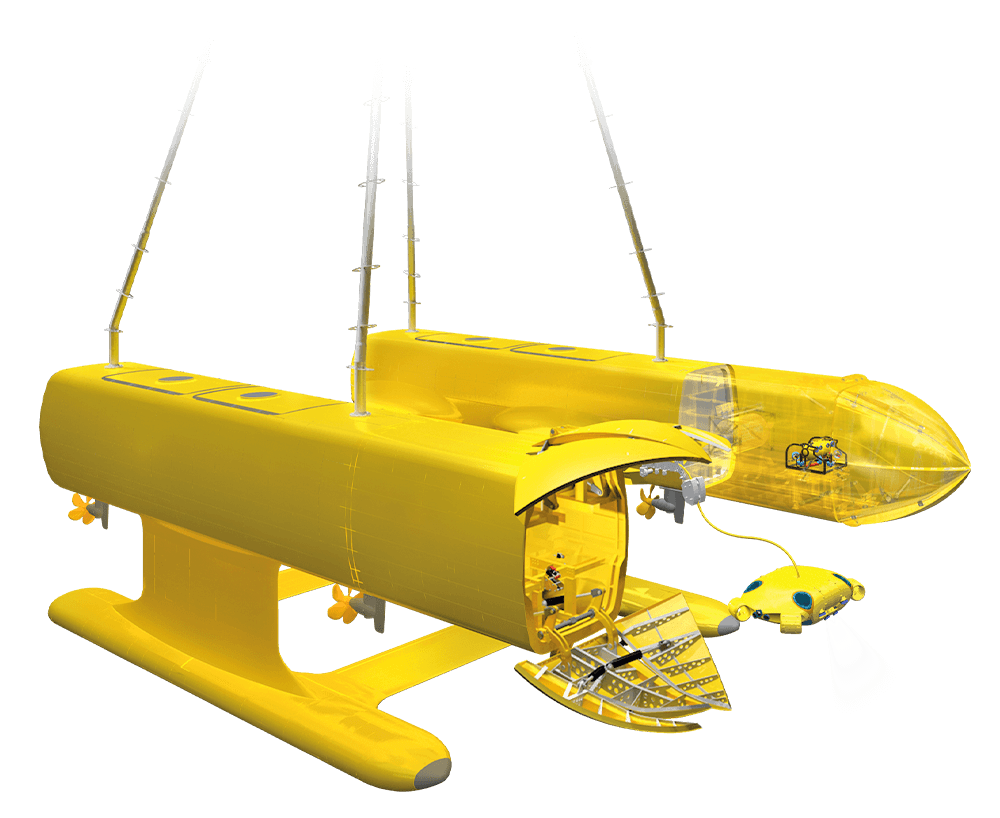

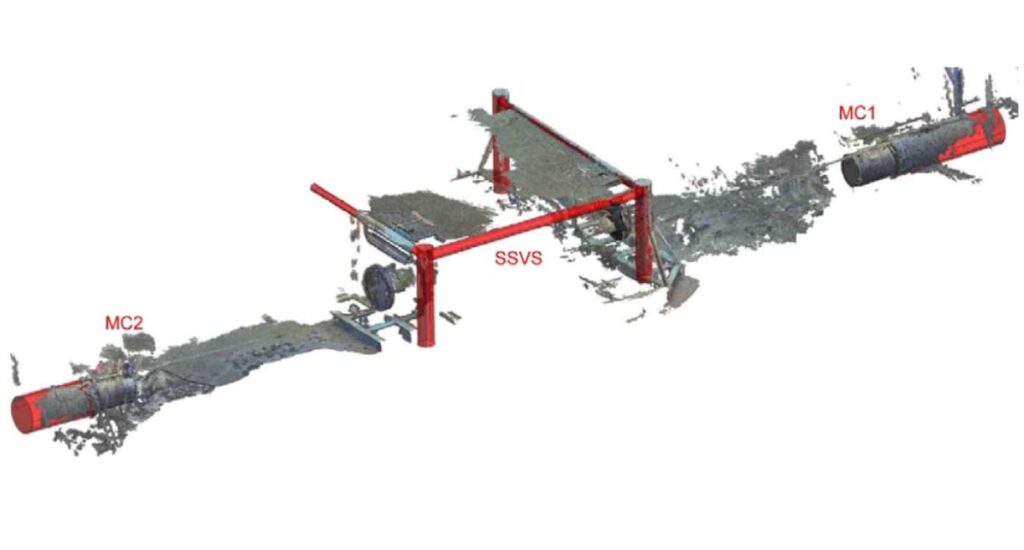

MCS Group presents a client case study illustrating the effective application of Photo Realistic 3D Cloud (PRC) for precise subsea measurements by an operator in the Gulf region. This technology was integrated during the Engineering, Procurement, Construction, and Installation of a Bypass Subsea Pipelines Network, utilizing subsea Hot Tapping. The adoption of PRC enabled the client to overcome challenges related to the project, ensuring remarkable accuracy and efficiency.

Challenges

Pushing the Boundaries of Measurement Accuracy

Our client faced significant challenges during the construction of the subsea pipeline network, including the need for precise measurements and high accuracy. The following key challenges were identified:

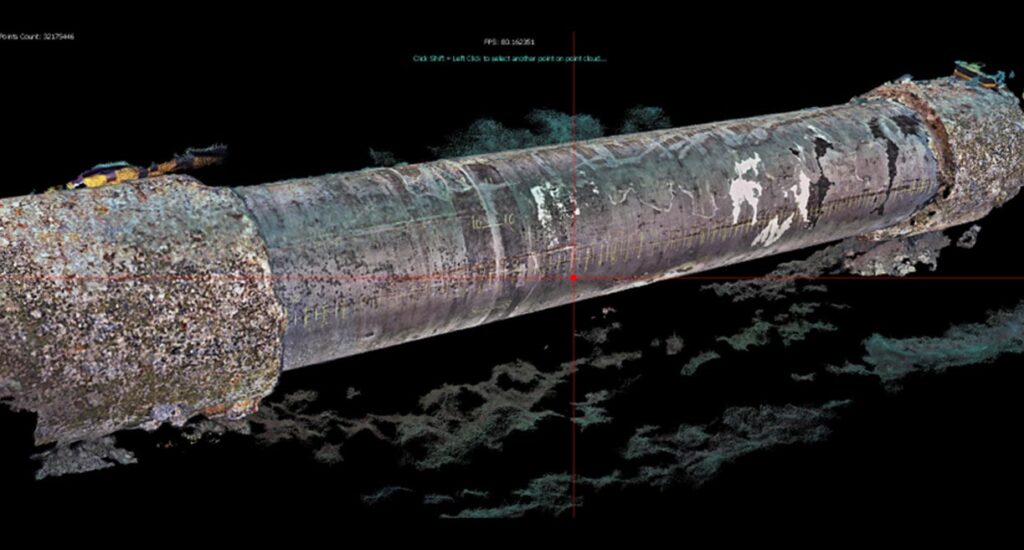

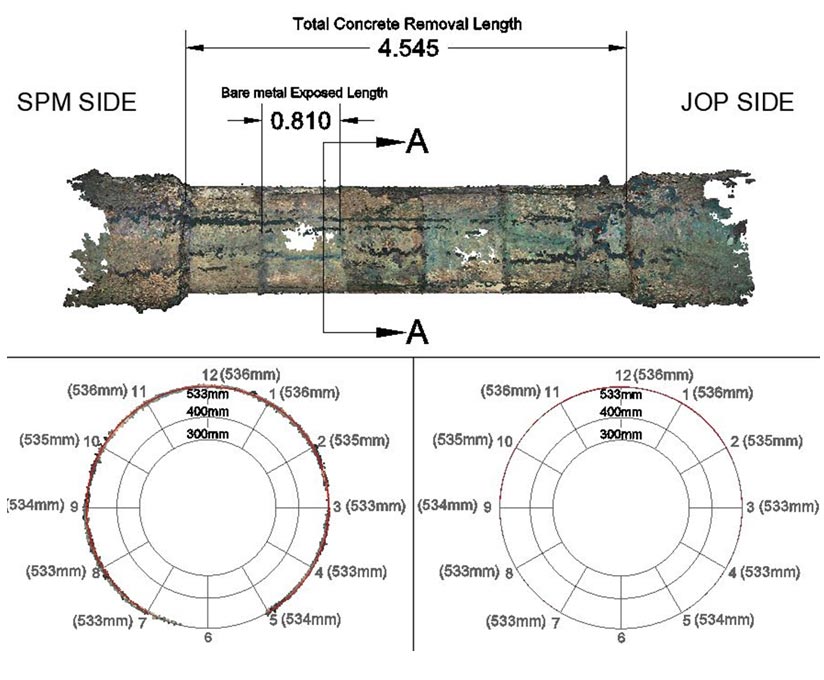

- Pipeline Ovality: Prior to cutting the pipeline, it was crucial to accurately assess its ovality to ensure seamless installation and operation.

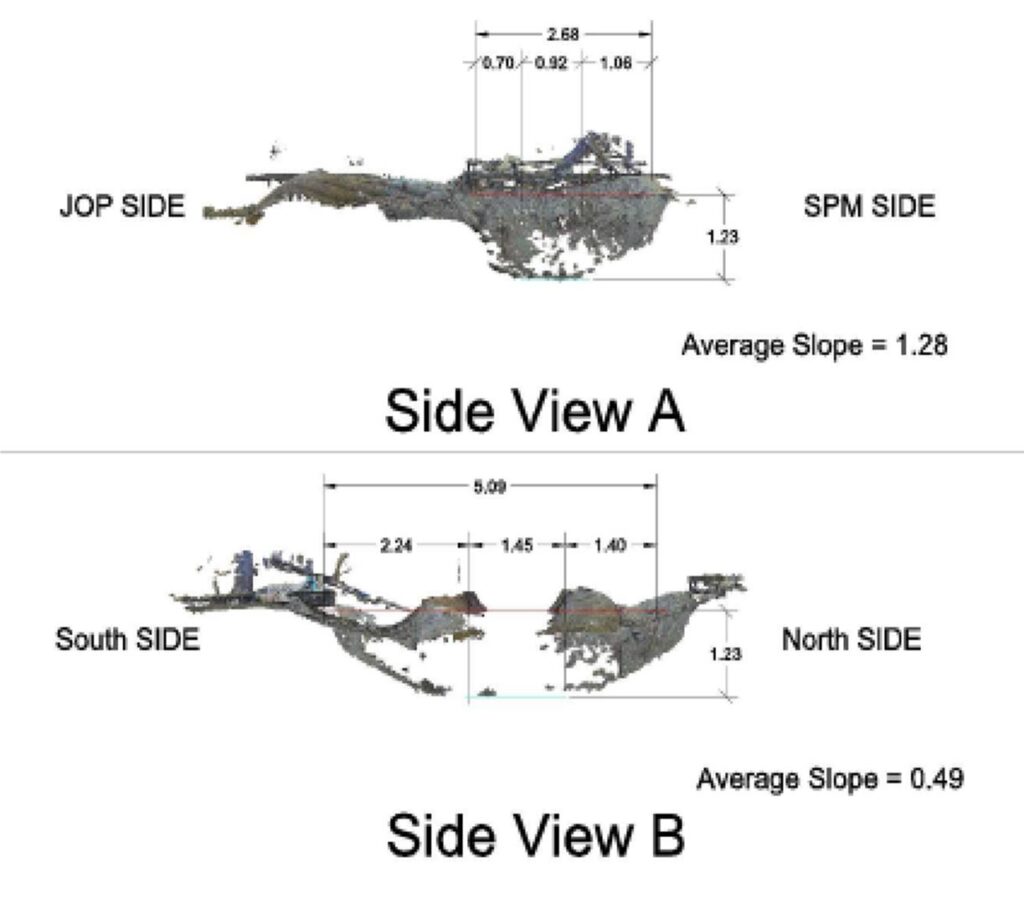

- Excavated Area Dimension: Obtaining precise dimensions of the excavated area beneath the pipeline was imperative to guarantee the correct positioning of the connector and hot tap.

- Seabed Profile: A thorough seabed profile analysis was necessary prior to valve skid installation to ensure installation stability.

- Distance Calculation and Spool Fabrication: Determining the distance between the mechanical connector and manufacturing the spool required meticulous measurements and precision to accommodate the pipelines’ large diameter.

- Spool Dimension Verification: It was critical to verify the spool’s dimensions after fabrication on board the vessel to ensure a flawless installation.

Solution

Optimizing Subsea Pipeline Projects with PRC

MCS Group and the operator combined efforts to integrate the advanced Photo Realistic 3D Cloud (PRC) technology. This technology addressed the project’s challenges effectively, offering metrologies with remarkable precision. With 3D imaging and point cloud capabilities, PRC presented detailed dimensional data, allowing the client to move forward with confidence and precision.

Outcomes

Elevating Subsea Pipeline Projects with PRC.

The operator’s adoption of PRC yielded several notable outcomes:

- High Accuracy: The client realized exceptional accuracy in pipeline measurements, ovality checks, and excavation dimensions, ensuring smooth installation and pipeline operation.

- Enhanced Safety and Stability: PRC facilitated a thorough seabed profile check, enabling the client to evaluate the stability of the area before installing the valve skid. This assessment ensured a safe and secure installation process, mitigating potential risks.

- Efficiency and Cost Effectiveness: Using PRC streamlined the distance calculation and spool fabrication, resulting in cost and time savings and reducing potential errors for large diameter pipelines.

- Smooth Installation: After ensuring the spool’s dimensions post-fabrication, the client experienced a risk-free installation onboard the vessel. This validation process minimized installation risks and guaranteed the successful completion of the project.

- Technological Leadership: By adopting PRC, the operator established themselves as a market leader, emphasizing innovative solutions for intricate subsea projects, setting a benchmark for future projects.

Incorporating Photo Realistic 3D Cloud (PRC) reshaped the processes associated with the Bypass Subsea Pipelines Network’s Engineering, Procurement, Construction, and Installation. Partnering with MCS Group enabled the client to utilize top-tier technology, ensuring unparalleled accuracy and enhancing project efficiency. MCS Group continues to champion innovation, aiming to transform the global energy and marine sectors.